About Niobium C-103 Alloy

In 1965, Niobium C103 alloy is first manufactured in America and then used in nozzle extended segment of Apollo manned lunar module rocket engine. In 1975, China succeeded in producing NbHf10Ti1Zr0.7 niobium alloy.

Niobium C103 Alloy is a niobium-hafnium-titanium) is a high-performance, heat resistant alloy typically used in aerospace components and other high temperature environments. American Elements’ niobium C103 meets ASTM B652, B653, B654, AMS7852 and AMS7857 grades and is available in standard and custom forms such as wire, sheet, bars, tubing, rods, and powders for additive manufacturing. Other shapes are available by request.

Niobium C-103 Definition

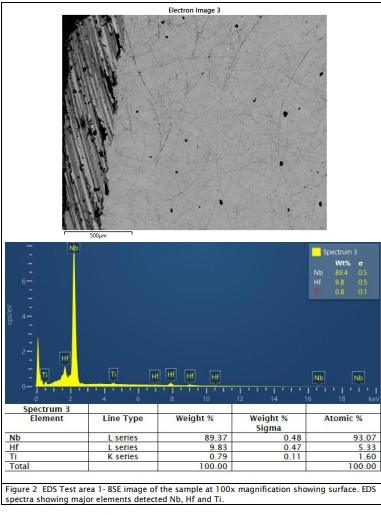

C-103 alloy (Nb-10Hf-1Ti-0.7Zr)

which is 89% Nb, 10% Hf and 1% Ti, is used for the rocket nozzle of the Apollo service module and the Merlin vacuum[3] engines; it is regarded as a medium-strength alloy.

Niobium C103 Alloy is a niobium-hafnium-titanium) is a high-performance, heat resistant alloy typically used in aerospace components and other high temperature environment

C-103 alloy is a Niobium based alloy that is widely used in aerospace applications because of its incredible heat resistance, as well as its light-weight, cost, reliability, and ability to stand up to intense vibrations and cryogenic temperatures. The alloy has a melting point of 2350 ± 50ºC, and a density of 8.85 gm/cm3, making it ideal for use in space, as well as for components used within super-heated thrusters, and rocket engines. The C-103 Niobium Alloy is widely employed in the manufacturing of scramjet engine components.

In 1965, Niobium C-103 alloy was first manufactured in America and used in the nozzle extended segment of the Apollo manned lunar module rocket engine.

C-103 Nb alloy is a complex refractory metal alloy consisting of niobium (Nb) with additions of 10wt% Hf (hafnium) and 1wt% Ti (titanium). Used almost since the beginning of the space age, C103 is a proven, well understood material offering exceptional mechanical strength and stability across the huge temperature ranges encountered in space (from cryogenic to high temperatures where the metal becomes red hot). C-103 Nb alloys are among the leading refractory metals used in propulsion and space exploration technologies.

C-103 Nb is an alloy comprised of carefully controlled amounts of niobium, hafnium, titanium, and additional alloying elements. Using a precise and complicated manufacturing process.

Niobium C103 Alloy Properties (Theoretical)

Compound Formula Nb/Hf/Ti Appearance Metallic solid in various forms Melting Point 2350 ± 50°C Boiling Point N/A Density 8.85 g/cm3 Solubility in H2O N/A Electrical Resistivity 0.0000313 - 0.0000352 ω-cm Specific Heat 0.082 BTU/°F/lb Thermal Conductivity 22.0 Btu/hr - ft2 - °F/ft (1600 °) Thermal Expansion 3.9 in/in/°F (400 °F) Monoisotopic Mass 320.801 g/mol

Chemical Composition of Niobium C103 Alloy

Niobium C103 Chemical Composition Maximum Weight % (Except Where Otherwise Specified) Products C O N H Hf Ti Zr W Ta C103 0.015 0.025 0.01 0.0015 9 - 11 0.7 - 1.3 0.7 0.5 0.500

Niobium C-103 Electron Images

Niobium C103 Alloy Welding

Niobium C103 alloy has good weldability. The welding methods include argon tungsten-arc welding and electron-beam fusion welding. Welding quality depends on the purity of argon and vacuum. The purer the argon and the lower remaining pressure is, the better the welding quality will be.

Niobium C103 Alloy Heat Treatment

Vacuum or inert gas protection is usually applied in the process of annealing, solution and aging treatment.

Benefits

- Readily weldable

- Excellent fabricability

- Capable of enduring high stresses at elevated temperatures

- Formable after TIG welding

- Low ductile-to-brittle transition temperature for cryogenic applications

Niobium C103 Alloy Specifications

ASTMB655

Standard Specification for Nionium-Hafnium Alloy Bar and Wire (C103)

ASTMB654

Standard Specification for Nionium-Hafnium Alloy Foil,Sheet,Strip and Plate (C103)

AMS7852

AEROSPCE MATERIAL SPECIFICATION Columbium (Niobium) Alloy Sheet,Strip,and Plate (10Hf-1.0Ti) (C103)

AMS7857

AEROSPCE MATERIAL SPECIFICATION Columbium (Niobium) Alloy Bars, Rods, and Extrusions 10Hf – 1.0Ti (C103)

Available Forms

XOT metals soutions partners with customers to produce and machine components for aerospace, including build-to-print and design of niobium C103 alloy parts.

- Bar and rod

- Ingot and slab

- Sheet and plate

- Fabricated parts

- Powder for Additive Manufacturing

Applications of Niobium C103 Alloy

Niobium C103 alloy is an excellent material for liquid rocket thruster nozzles, lightweight propulsion systems and rocket engine thrust chamber in aerospace industry. Niobium C103 alloy is also used in the manufacture of turbopump and high-temperature jet engine parts. It is obvious that Niobium C103 alloy is an ideal material in space engineering fabrication and welding production

For more detail or technical support of C103, please contact us.