Inconel 625 ( UNS N06625) is a nickel-based superalloy with excellent resistance to oxidation and corrosion. The nickel-chromium matrix of this material is reinforced by the addition of molybdenum and niobium, which is alloyed through solid solution strengthening. This process allows alloy 625 to maintain high strength and toughness at temperatures ranging from cryogenic up to 1800°F (982°C). It is non-magnetic, austenitic, and displays high tensile strength, fabricability, and brazeability. Due to its high nickel content, this alloy is nearly immune to chloride ion stress-corrosion cracking and pitting, which is commonly found in thin-walled seawater applications like heat exchangers, fasteners, and cable sheathing.

In addition to sheets, bars and forgings, XOT stocks commercial and industrial clients with high-quality Inconel 625 plates. Inconel 625 is a specialty super alloy that is widely used in the aerospace, chemical processing, marine, hardware manufacturing and power generation industries, thanks to its versatility and performance under great stress and extreme temperatures.

Specification of Inconel 625 Plate

625 Plate, Sheet, and Coil ASTM B 443

Thickness

Ranging from 0.3mm to 20mm

Length

2000 mm / 2440 mm / 2500 mm / 3000 mm / 6000 mm

Width

1000mm / 1219mm /1250mm / 1500mm / 2000mm

Finish

Hot rolled plate (HR), Cold rolled sheet (CR)

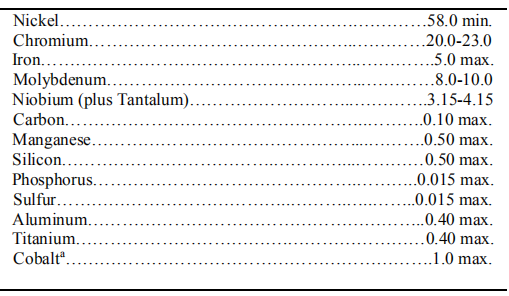

Chemical composition

Properties of Inconel 625 plate

Inconel 625 plates are supplemented with a columbium-tantalum alloy, as well as molybendum and chromium constituents. Certain preparations also feature significant amounts of carbon, iron, silicon, manganese, sulfur, phosphorus, titanium, cobalt and aluminum.

Working with Inconel 625

Alloy 625 can be cold formed, hot worked, and machined through most standard methods. Hot forming should be done at temperature ranges of 1700 – 2150°F (927-1177°C), and care should be taken when cold working and machining, as it work hardens more quickly than more traditional austenitic stainless steels. Recommend using rigid, powerful machines with sharp tooling at positive rake angles, with tools changed frequently to maintain sharpness. Heavy constant feeds are advised to maintain a positive cutting action with proper lubrication. All 625 may be welded through typical gas shielded processes.

Fabrication of the sheet & plates

The fabrication of Inconel 625 Sheet & Plate is done under the strict guidance of professional experts that know everything clearly about the production. The production of the sheet and plates are done by making effective use of high quality of Inconel alloy. The sheet & plate effective fabrication has become possible because of the proper use of the latest technology and modern tools.

Features of Inconel 625 plate

- Heat and cold resistance

- Chloride stress resistance

- Corrosion cracking resistance

- Salt, fresh water and alkaline chemical resistance

- Stability during welding

- Scaling and oxidization resistance

Application

- Heat shields

- Production tubes for sour gases

- Industrial tubing and piping

- Spray bars

- Chimney liners

- Bubble caps

- Distillation columns

- Furnace hardware and heat exchangers

- Reaction vessels

For more details, please contact us.