Physical Properties

Interconversions of solids, liquids and gases are widely understood, but the shape-memory effect for nitinol results from a temperature-dependent phase change that occurs exclusively in the solid state, known as a thermoelastic martensitic transformation.When normal metals are deformed, dislocations and re- positioning of atomic planes within the crystal ac- cumulate into tangles that resist further deformation, a process called work hardening. SMA respond to deformation completely differently by undergoing transition in their metallic crystal structure when heated or when stress is applied.

At lower temperatures, SMA have a readily de- formable crystalline arrangement termed martensite. The metallic cells are slightly tilted in bands that are microscopically visible as a ‘‘tweed’’ or ‘‘herringbone’’ pattern properly described as a ‘‘monoclinic’’ con- figuration. In addition, each band is internally tilted in the same way, forming a crystal of great complexity. As the martensite is deformed, these complex bands can move to accommodate the strain generated in the metal. In this way, no dislocation of the metallic lattice takes place and irreversible plastic deformation does not occur, provided the strain limits of the alloy are not exceeded.

Manufacture

Nitinol can be manufactured to ‘‘remember’’ a cus- tomised shape. SMA are usually processed by rolling or forging the alloy under heat, then by a series of cold working phases, and finally by a carefully controlled heat treatment to 450–550 °C for 1–5 min during which the alloy is constrained on a mandrel or fixture to form desired shapes. This process is referred to as ‘‘shape training’’. After this treatment, heating the alloy to above the TTR results in recovery of the ‘‘memorised’’ shape. The TTR can be manipulated to occur between −200 to +110 °C by varying the nickel content of the alloy, by adding small amounts of other metals such ascopper or niobium, or by separate heat treatments. The Active Austenite Finish temperature (Af) is the upperend of the TTR at which conversion to austenite is complete, and careful control of this value is crucial to commercial and medical applications of the alloy.

Commercial Applications

Various commercial devices utilise the thermal shape memory characteristics. A pipe coupling system used for high-performance hydraulic systems in military aircraft and naval ships has sold over one million units without a single service failure. The product is shippedand stored in a martensite pre-expanded form in liquid nitrogen. The ends of the tubes to be joined are inserted into each end of the nitinol coupling which reverts to its contracted austenite form in the ambient temperature,resulting in a strong permanent union. The automatic transmission of diesel-powered Mercedes Benz automobiles contains a nitinol-actuated valve that regulates the flow of transmission fluid as a function of tem perature, smoothing transition between gears. Other uses include anti-scalding valves in showers, activators for fire sprinklers, and switches in coffee-makers.

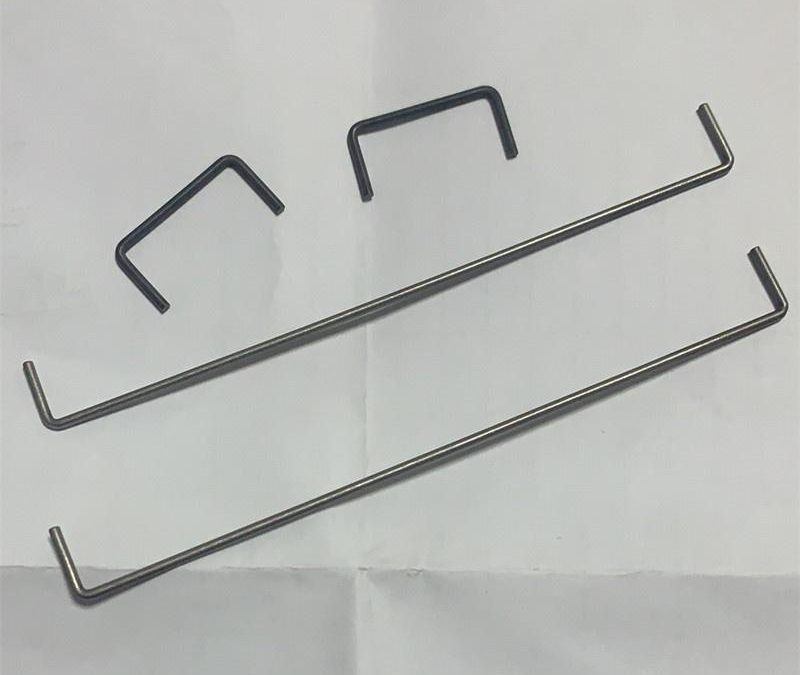

The superelasticity and damping properties lead to other commercial applications. Nitinol is used in special bolts, latches, couplings, coil springs on engine mounts and suspensions, and connectors for aircraft and spacecraft frames. It forms the basis for earth-quake-resistant reinforcement in buildings, and evenin instruments to tune guitar strings. It was used to activate a system on the Sojourner Rover to accumulate dust from Mars during the Pathfinder Mission. Nitinol is used for antennae for cellular telephones and NASA spacecraft. Nitinol spectacle frames that can be deformed but which are virtually indestructible constitute a US $100 million annual market.SMA form stitute a US $100 million annual market. SMA form robots such as the Lobster Seabed Crawler. Nitinol underwire brassieres are popular

If you don’t find what you want, we will custom-build it for you.Contact us.

.