What is C-103 Nb Alloy?

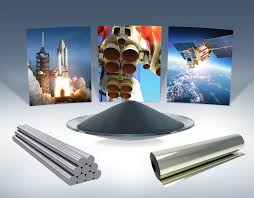

C-103 Nb is an alloy comprised of carefully controlled amounts of niobium, hafnium, titanium, and additional alloying elements. Using a precise and complicated manufacturing process, we produce C-103 Nb alloys with extremely consistent microstructure resulting in exceptionally well controlled material properties.

We work closely with customers to supply a variety of C103 products including bars, rods, sheet, plate, ingot, slabs, powders, and custom fabricated parts.

If you are considering C-103 Nb, simply contact a member of the XOT metals design team today with any questions.、

Available Forms and Fabrication

XOT metals collaborates with customers to fabricate and machine components for aerospace, including build-toprint and design of niobium C-103 alloy components.

| Niobium C103 Material | Dimensions inches | Dimensions cm |

|---|---|---|

| Bar and Rod | 1.5 in. - 6.5 in. diameter | 3.81 cm - 16.51 cm |

| Sheet | 0.024 in. - 0.1875 in. thick, up to 24 in. width | .06 cm - .48 cm, up to 61 cm width |

| Plate | 0.1875 in. - 1 in. thick, common widths | .06 cm - 2.54 cm |

| Ingots | up to 9.5 in. diameter | up to 24.1 cm |

| Slabs | as requested | |

| Niobium C- 103 Powder | additive manufacturing | |

| Fabrication Parts | per customer specification |

XOT metals’ C-103 niobium alloy meets ASTM B652, B654, B655, AMS7852 and AMS7857 specification.

XOT metals’ C-103 niobium alloy powders are available for additive manufacturing applications in both flake and spherical morphologies

C103 powder

Morphology: Spherical

Specification

| Property | Coarse | Fine |

|---|---|---|

| Nominal PSD (µm) | 50-180 | 15-50 |

| D10 (µm) | 53-65 | 20-30 |

| D50 (µm) | 85-99 | 30-40 |

| D90 (µm) | 155-175 | 40-50 |

Applications

Niobium powder can absorb gas, which use as degasifier. It is also great superconductor at low temperature. Niobium is the third elements that is one of the II category superconductor after vanadium and technetium. The purity of niobium will affect its superconducting property.

Niobium ingot apply to high-temperature alloys normally, for examples inconel 718, C-103, FS85, Cb129Y, Cb752 and Nb1Zr. Inconel 718 is a kind of Ni-Nb alloy, which contain Ni 50%, Cr 18.6%, Fe 18.5%, Nb 5%, Mo 3.1%, Ti 0.9% and Al 0.4%. C-103 is a kind of niobium alloy, which contains 89% Nb, 10% Hf and 1% Ti.

Niobium powder is for welding electrode production normally. There are different kinds, FNb-1, FNb-2 and FNb-3. Niobium metal powder get common uses in niobium capacitor of circuit board, due to its high dielectric constant and stable oxide media.

Niobium sheets, niobium wires, niobium rods, niobium pellets and niobium tubes get applications in sputtering target, cathodic protection system and chemical reactor, due their corrosion resistance, forming oxide nitride films, oxidation resistance, strong creep resistance, reducing high temperature corrosion.

The most important superconducting material is Nb-Ti and Nb-Sn, which are widely used in MRI for medical diagnosis and NMR for spectral analysis.

Aerospace industry is the main application field for high purity niobium, which focus on producing engine and heat-resistant parts of rocket and airship. The Nb-Ta alloy owns good heat resistance and processability, which is widely used in producing engine parts of aviation and blade of gas turbine.

Additive Manufacture of Refractory Alloy C103 for Propulsion Applications

C103 is niobium alloy used in high temperature operating environments. Traditional manufacture methods suffer from feedstock constraints, difficult to machine, high buy-to-fly ratios, and high costs resulting in a limited number of suppliers. Additive manufacture (AM) offers advantages in production of complex parts, improved properties, reproducibility, with significant material cost and schedule savings. C103 proved feasible, increased design flexibility, improved mechanical properties compared to wrought, and resulted in an order of magnitude cost reduction.