Brief Introduction of Shape Memory Alloy

A shape-memory alloy (also know as SMA, smart metal, memory metal, memory alloy, muscle wire, smart alloy) is considered one of the most promising smart materials on the market today. They can provide novel solution in several fields, for various applications (e.g. actuator, biomedical application, clamping systems, etc.). Among the commercially available Shape Memory Alloys, nickel-titanium (Ni–Ti and Ni–Ti based) ones are outstanding due to their excellent performance, reliability, and strain recovery properties. Ni–Ti is attractive for medical applications due to its biocompatibility, corrosion resistance, and fatigue behavior.

NiTiCu shape memory alloys

Typical performance and application examples

| Item | Actual operating temperature Af(℃) | Typical application |

|---|---|---|

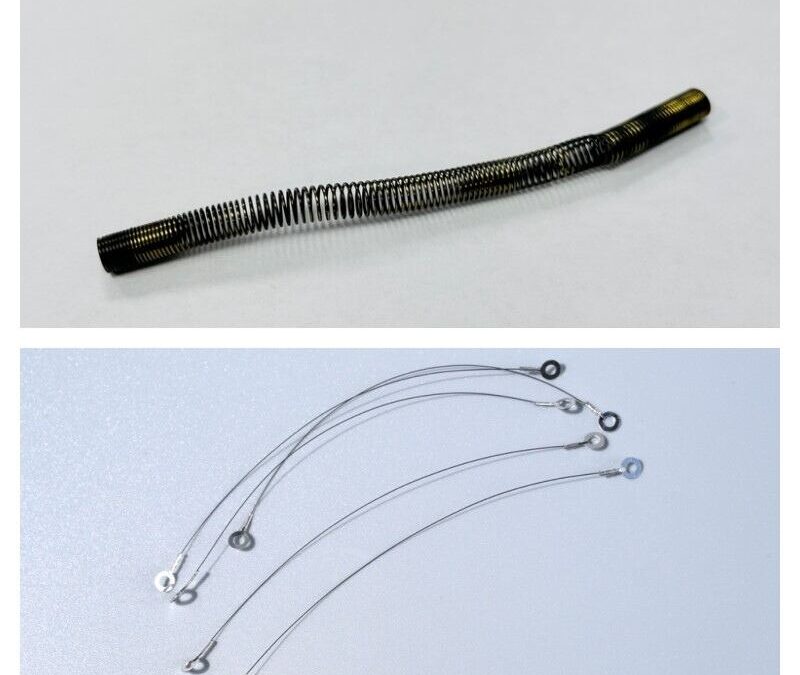

| NiTiCu Wires | 50~70 | Narrow hysteresis driver, Temperature control spring, Electric contraction wire, etc |

With high precision ratio, high purity of sponge titanium and nickel particles under the condition of high vacuum after vacuum electromagnetic induction heated mixing smelting, make ingot casting a superfine crystal alloy, reach or exceed the standard required by the composition of ingot casting, thus ensuring minimal ingredients evenly, stable phase transition point, at the same time in the process of preparing raw material control the impurity element such as nitrogen, oxygen content, It is ready for the preparation of fine crystal filament. XOT has obtained the invention patent authorized by the State Property Office in January 2020 “preparation method of a high purity NiTiCu shape memory alloy ingot” (patent number: ZL201910163666.1).

The use of our research and development of independent technology: ultra-fine wire deep processing technology and ultra-fine wire surface treatment technology has played a good technical guarantee for the smooth progress of the project, suitable for mass automatic production. The prepared products have excellent performance, surface quality and fatigue performance reach the frontier level of similar products.

The main characteristics of NiTiCu alloy are super-elasticity and memory. Compared with ti-Ni two-element alloy, adding the third element will make the performance different, and its deformation times can reach tens of millions of times without fracture.

Applications of NiTiCu Alloy

NiTiCu alloy has greatly expanded the application field of memory alloy, electromagnetic couplers, temperature sensors, microelectronics and optical devices, information storage media, and artificial heart valves in the medical field have a wide application potential. In addition, the memory alloy can be used to convert heat from the outside and environment into electricity, or to develop new cooling units

.-Medicine

Shape-memory alloys are applied in medicine, for example, as fixation devices for osteotomies in orthopaedic surgery, in dental braces to exert constant tooth-moving forces on the teeth.

– Nitinol is being used in robotics actuators and micromanipulators to simulate human muscle motion. The main advantage of Nitinol is the smooth, controlled force it exerts upon activation.

– Other miscellaneous applications of shape memory alloys include use in household appliances, in clothing, and in structures.

XOT metals is a leading supplier of Shape Memory Alloy. We provide not only Ti-Ni memory alloy, but also NiTiCu shape memory alloys. For more information, please do not hesitate to get in touch with our friendly team today.