Benefits of Electropolishing Nitinol Alloy

Electropolishing Nitinol improves the Nitinol alloy ’s resistance against corrosion as well as improves its durability by performing several different functions at once.

Nitinol Microfinishing

Corrosion Resistance: finally, electropolishing eliminates surface imperfections, which could become initiation sites for corrosion. Eliminating these surface imperfections and other impurities improves the metal’s resistance to corrosion.

Microfinishing: electropolishing removes a uniform, controlled amount of material from the surface of the metal or alloy. The removed material ranges from .0001” to .0015” per surface, and allows for accurate sizing of Nitinol parts without distorting or changing their shapes.

Deburring: Nitinol alloy must be burr-free when used in medical applications for optimal safety. Electropolishing is an effective method for removing burrs, leaving the surface of the metal free of micro-imperfections that can have a negative impact on performance.

Ultracleaning: electropolishing also removes debris and other embedded contaminants—an essential feature for medical devices. This is most beneficial for implantable medical devices, which must be sterile prior to implantation. Additionally, it provides a clean, bright appearance.

Progress in Electropolishing of medical nitinol alloy

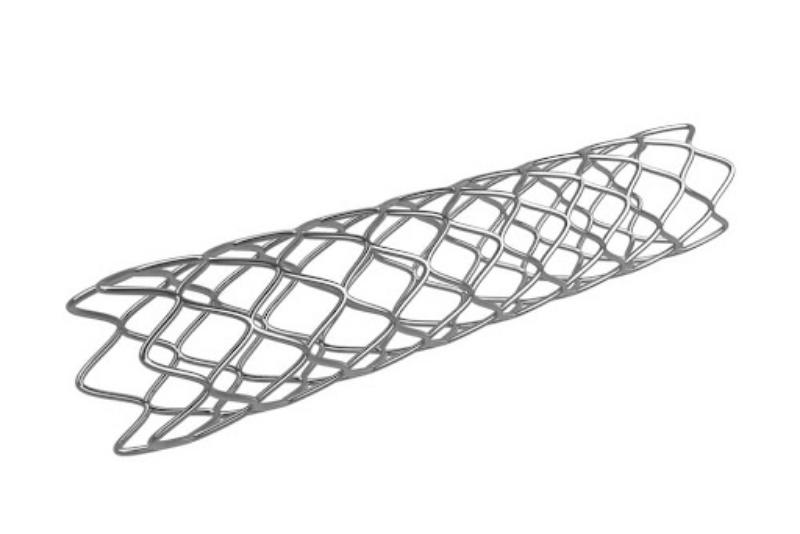

Nitinol has unique shape memory, superelasticity, good mechanical properties, friction resistance, corrosion resistance and biocompatibility, making it an ideal material for the manufacture of vascular stents in medicine. Urgent attention. However, if the Nitinol stent has not been processed, it has a high roughness, and after implantation in the human body, there will be greater resistance to the blood flow at this place, resulting in the formation of thrombus. Therefore, the surface treatment of the nickel-titanium stent is improved. Its surface properties have become the key to the preparation of medical Nitinol alloy stents. In the industry, the surface treatment of nickel-titanium alloys is generally performed by a combination of mechanical polishing and chemical polishing, but the efficiency of mechanical polishing and chemical polishing is low, the process is cumbersome, and it is special for stents. The material of the structure is particularly susceptible to damage. Therefore, the industry usually uses electropolishing technology as the main processing method for the surface treatment of Nitinol stents.

Electrolytic polishing technology is one of the important processes for surface treatment of metals. This method uses pretreated workpieces as anodes and strong corrosion-resistant materials as cathodes. The cathodes in production are generally stainless steel or Nitinol alloy with strong corrosion resistance. Lead, etc.. It is required to reduce the surface roughness of the material under the energized condition, improve its corrosion resistance and friction resistance, and finally obtain a smooth and bright appearance of the anode treatment process. This treatment process has little damage to the bracket and high polishing efficiency. A common method for surface treatment of bracket-type workpieces in production.

With the gradual increase in the market’s requirements for the roughness, gloss and corrosion resistance of metal materials, electrolytic polishing technology, as a precision surface processing technology, has the characteristics of high efficiency, smooth surface of processed samples, and ability to maintain the original performance of the material. It has developed rapidly in the field of surface treatment. Three types of electrolytic polishing liquid systems are popular in the industry: acid-acid system, acid-alcohol system and alcohol-salt system and their main components. Electrolytic polishing under different electrolytic polishing liquid system components is analyzed. The influence of changes in liquid concentration, polishing temperature and polishing voltage on the polishing effect (roughness, corrosion resistance) and polishing efficiency. The advantages and disadvantages of different electrolytic polishing liquid systems are further compared, and the principle, mechanism and technology of electrolytic polishing are introduced. new development.

Regarding the new technology of electrolytic polishing, it is still based on the improvement of the polishing device. At present, there are evidences including magnetic grinding technology, ultrasonic polishing technology, pulse voltage technology and electrolytic plasma polishing technology.

Magnetic abrasive electrolytic polishing technology

Magnetic grinding and electrolytic polishing technology uses an external magnetic field to act on metal ions, thereby reducing the surface roughness of the material. Magnetic grinding technology to reduce the surface roughness of the material. Through the intervention of an external magnetic field, the removal rate of the anode surface material can be improved, and the surface of the material can be uniform , Leveling. By studying the principle of polishing and conducting a large number of polishing experiments under magnetic field conditions, the mechanism of electrolytic polishing under magnetic grinding conditions is analyzed.

Ultrasonic polishing technology

Ultrasonic polishing technology uses ultrasonic vibration to improve polishing efficiency. It can improve the heterogeneous reaction speed, promote the progress of the reaction and the diffusion of the product. By studying the electrolytic polishing technology under ultrasonic conditions, it is concluded that under the conditions of ultrasonic vibration , Not only can reduce the roughness of the sample surface, but also increase the content of titanium in the oxide film. This is of great help to the improvement of the biocompatibility and corrosion resistance of the material.

Pulse voltage polishing technology

The idea of this equipment stems from the difficulty of controlling viscous electrolytes and various additives during the polishing process. Electrolytic polishing using pulse voltage, the aqueous solution is highly conductive, easy to control, and simple to operate. The instantaneous current will exceed the direct current to a certain extent The material removal rate will be higher than the DC voltage.

Electrolytic plasma polishing technology

Plasma polishing technology is a surface treatment technology based on the high-voltage effect of the aqueous electrolytic polishing solution, and the plasma discharges on the anode surface to achieve the polishing effect. This polishing technology based on plasma impact. This technology is mostly used for polishing complex shapes or highly conductive polishing fluids composed of salts.

With the continuous improvement of the industry’s requirements for electrolytic polishing technology, the cross-matching use of different electrolytic polishing liquid systems has gradually become a trend in the technological development process. Here, a stable and harmless environmental protection based on inorganic salts-alcohols is established. Electrolytic polishing liquid is a necessary requirement for the development of electrolytic polishing surface treatment technology. Under this premise, starting from the polishing mechanism, the electrolytic polishing device is upgraded, and an efficient electrolytic polishing liquid and a correspondingly stable electrolytic polishing process have been developed, with the help of the latest polishing technology Improving polishing efficiency is the key to further research on electrolytic polishing surface treatment technology. With the continuous improvement of this technology and the evening, it will inevitably promote the application of Nitinol wire, Nitinol plate, and Nitinol tube in oral, orthopedics, and cardiac healing, and provide medical services with better biocompatibility for the majority of patients.

To learn more about our processes for electropolishing medical devices, including specialized processes for nitinol alloy,please contact us.