About Copper Sputtering Target

XOT Metals specializes in producing high purity Copper sputtering targets with the highest possible density and smallest possible average grain sizes for use in semiconductor, chemical vapor deposition (CVD) and physical vapor deposition (PVD) display and optical applications. Our standard Sputtering Targets for thin film are available monoblock or bonded with planar target dimensions and configurations up to 820 mm with hole drill locations and threading, beveling, grooves and backing designed to work with both older sputtering devices as well as the latest process equipment, such as large area coating for solar energy or fuel cells and flip-chip applications. We offer all shapes and configurations of targets compatible with all standard guns including circular, rectangular, annular, oval, “dog-bone,” rotatable (rotary), multi-tiled and others in standard, custom, and research sized dimensions. All targets are analyzed using best demonstrated techniques including X-Ray Fluorescence (XRF), Glow Discharge Mass Spectrometry (GDMS), and Inductively Coupled Plasma (ICP). “Sputtering” allows for thin film deposition of an ultra high purity sputtering metallic or oxide material onto another solid substrate by the controlled removal and conversion of the target material into a directed gaseous/plasma phase through ionic bombardment. Materials are produced using crystallization, solid state and other ultra high purification processes such as sublimation.

Application of high purity copper

- IC bonding wire, HIFI headphone cable

- Quantum computer, dilution refrigerating machine, low temperature refrigerating machine, heat sink and heat transfer components for non-liquid helium superconducting magnets

- Superconducting wire matrix material

- Sputtering target, evaporation target, rotating target

- RFQ acceleration cavity

Application of high RRR copper

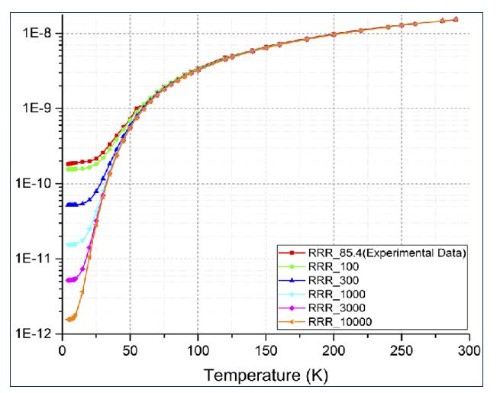

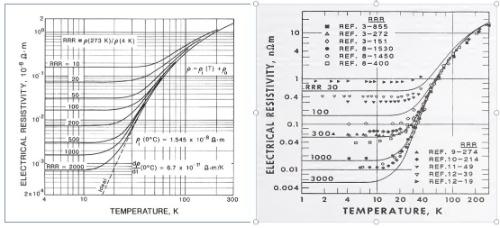

Low temperature resistance and heat transfer characteristics of high RRR copper

Low temperature resistance and heat transfer characteristics of high purity copper

We produce High purity copper and high RRR copper Plate, tube, ingot, rod, wire, ultra-fine wire and woven tape, various blocks and processed parts. Other shapes are available by request.

High purity copper plate

Cu 99.9999

Thickness: 0.5-100mm

Purity:5N~7N

Size:The length, width, thickness,Weight can be customized according to customer requirements

High purity copper ingot, copper bar

Common specifications: Φ280mm*L

Φ 410 mm * L

Purity:4N5、5N、6N

Sizes:

Round blank: Φ200mm-Φ850mm

Square blank: 900mm X 900mm

Specifications: The height/thickness, grain size can be customized according to customer requirements

High purity copper target

Advantage:Smooth surface, high density, no tissue defects, good homogeneity.

Purity:5N~6N5

Sizes: The length and diameter of high purity copper particles can be customized according to customer requirements

High purity copper wire

Purity:5N~6N5

Sizes:φ10-70 microns,

Can be customized drawing production according to customer requirements

High purity copper powder

Advantage:High spherical of the product.

Purity:4N5~5N

Sizes:Powder fineness 50-1000 mesh, can be customized according to customer needs.

Porous oxygen free copper ingots and oxygen free copper tubes for superconductors(RRR>200)

For Nb3Sn、NbTi、MgB2

Sizes:

φ280mm/φ247mm*900

φ253mm/φ193mm*900

φ56mm/φ40mm*L