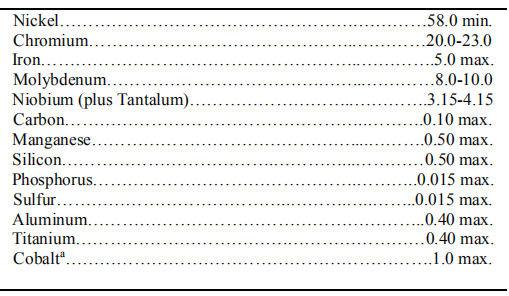

Inconel 625 is a high-performance nickel-chromium-molybdenum alloy known for its high level of strength, temperature resistance, and corrosion resistance. This superalloy is composed mainly of nickel (58% min.) followed by chromium, and molybdenum, niobium, iron, tantalum, cobalt, and trace amounts of manganese, silicon, aluminium, and titanium. Inconel 625 also commonly goes by the names: Haynes 625, Altemp 625, Nickelvac 625, and Nicrofer 6020.

Exceptional material strength

The strength of Inconel625 lies not only in its nickel-chromium base but also the hardening mechanism of niobium and molybdenum. The alloy matrix is strengthened by the interaction of niobium with molybdenum that offers high strength without the need for precipitation-hardening treatment. The tensile strength of this superalloy is 690 MPa, while its yield strength measures 275 MPa.

High temperature resistance

With a melting point of about 1300°C and a thermal expansion coefficient of 1.28 x 10-5 1/K (at 20°C), Inconel 625 resists a wide range of temperature extremes from cryogenic to extremely high.

At high temperatures in the presence of oxidising agents, the titanium and niobium compositions of the oxide film on Inconel 625 increase drastically to form a natural protective layer in the material.

Corrosion resistance

The unique combination of its components makes Inconel 625 highly resistant to corrosive substances. This is the reason why this superalloy works excellently under high saline seawater, and more so in milder environments such as fresh water and standard atmospheric conditions.

Upon exposure to oxidising agents, Inconel 625 is protected naturally by its nickel-chromium matrix. Meanwhile, molybdenum protects the material against pitting corrosion. In 15% sulfuric acid, the material corrodes at a minimal rate of 0.188 mm per year.

High level of fabricability

Inconel 625 was designed to have better weldability than earlier alloys, with no signs of cracking when exposed to strain and temperature changes post-welding. Its high creep resistance and yield strength make this superalloy a good choice for tubes, piping, and plant equipment that require welding.

Chemical composition

Available Shapes: Bar,Rod,Pipe,Wire,Strip,Plate,Sheet,Spring,Fittings

| Bar | Forging | Sheet/Strip | Wire | Pipe |

|---|---|---|---|---|

| ASTM B446 | ASTM B564 | ASTM B443 | ASTM B446 | ASTM B444 ASTM B704 ASTM B705 |

Features of Inconel 625

- Outstanding resistance to chloride pitting and crevice corrosion cracking

- Immune to chloride ion stress corrosion cracking

- Resistant to caustics

- Resistant to seawater, in both flowing and stagnant • conditions, and under fouling

- Applications of Inconel 625

Typical Applications for the Inconel 625 include:

- Chemical process equipment handling mixed acids both oxidizing and reducing

- Flue gas desulfurization scrubbers

- Evaporators for wet-process phosphoric acid containing H2SO4, HF and ferric salts

- Weld Overlay

we use flexible and custom manufacturing which allows us to provide our customers with the exact amount and shape of Inconel 625 alloy that they need. Contact us for details.