Superconducting material

Materials with superconductivity under certain conditions (temperature, magnetic field, current, etc.) are superconducting materials.

Classification of superconducting materials

Classified by Tc

- Low temperature superconducting materials (NbTi, Nb3Sn, Nb3Ge)

- High temperature superconducting materials (Y series and Bi series)

Classified by composition

- Metal (Nb)

- Alloy (NbTi, NbZr)

- Compound (Nb3Sn, V3Ga, PbMoS)

- Oxide (YBCO, BSCCO)

Classified by application:

- Strong current application (wire, block)

- Weak current application (membrane)

Properties of NbTi superconducting material

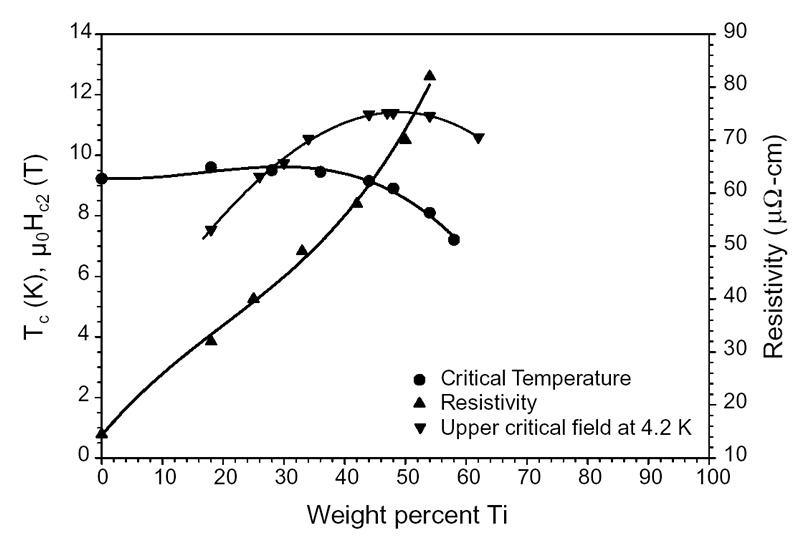

The critical temperature Tc, the upper critical magnetic field μ0Hc2, and the resistivity at 293K of NbTi alloy at 4.2K

Critical current density

This is a very important parameter for practical superconducting materials Influence NbTi superconducting wire.

The macroscopic factor is the continuity and uniformity of superconductors.

The microscopic factor is the nailing center structure dominated by the second phase and dislocation cells.

Features of NbTi alloy superconducting material

- Excellent mechanical processing performance;

- Good superconductivity and its uniformity;

- Lower use cost

Traditional production process of NbTi alloy superconducting material

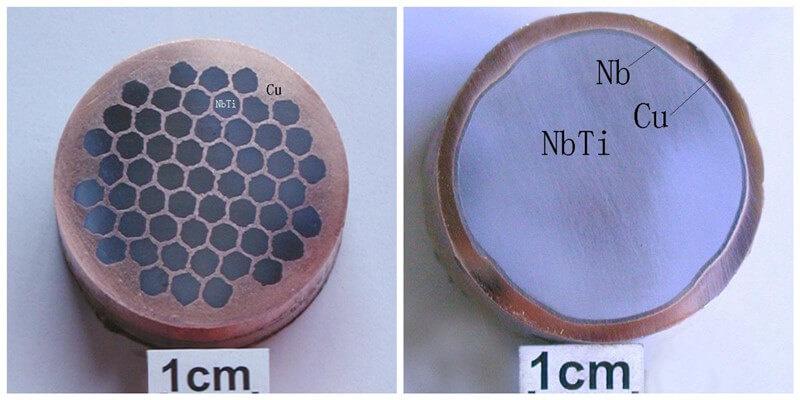

The preparation of traditional NbTi/Cu multi-core superconducting wires generally includes alloy preparation, alloy rod processing, multi-core complex combination and processing, heat treatment of multi-core superconducting wires and other technological processes

Production process of of NbTi/Cu superconducting wires

Conductor design:

Design process parameters and process routes according to user requirements (core diameter, copper over-ratio, wire diameter, etc.), calculate the number of cores, determine the complex copper process and the multi-core assembly plan.

Package design and matching scheme:

determine the extrusion equipment and the matching scheme of the ingot inch mandrel, package design, mandrel size and quantity, and the additional size of copper material

Assembly and preparation of extruded billet (wrap)

Encapsulation welding

Extrusion process

Processing of composite rod (NbTi/Cu)

Multiple aging and final additional deformation process

Two important characteristics of superconductors: zero resistance and diamagnetism.

Meissner effect-completely diamagnetic

In 1933, Meissner and Olsenfeld of the Netherlands jointly discovered another extremely important property of superconductors. When the metal is in a superconducting state, the magnetic induction intensity in the superconductor is zero, and the magnetic field (magnetic field lines) that originally existed in the body. Be pushed out. People call this phenomenon the “Meisner effect.

Applications of superconducting materials

- High-current applications (high-current applications) : power generation, transmission and energy storage

- Electronics applications (weak current applications) : superconducting computers, filters, microwave devices, etc

- Diamagnetism application: maglev train and thermonuclear fusion reactor, etc

In the near future, China’s energy, medical and health, electronic technology and scientific instruments and other aspects will be in urgent need of superconductivity technology. The United States, Japan and other countries on the superconductor product market estimates, China as one of the important markets.

If you would like to know more about superconducting materials, please feel free to contact us.