NbTi superconducting wire fabrication process

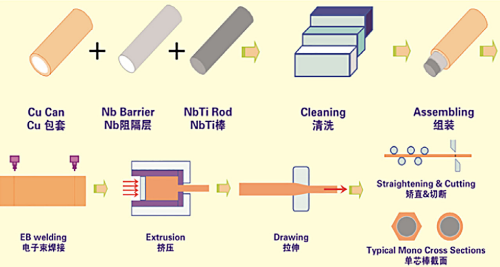

The fabrication process from a NbTi alloy bar or billet to superconducting wires usually includes two main steps: monofilament bar fabrication and multifilament bar/wire fabrication.

NbTi bar, Nb barrier, and Cu can are cleaned and then assembled together(see Fig. 8). Nb barrier is warped around the NbTi bar to avoid the reaction of Ti and Cu during the precipitation heat treatment. The assembled billet is welded by electron beam in a vacuum condition. A subsequent warm extrusion is used to make the three components well bonded. By cold drawing, a monofilament bar is fabricated.

Fig. 8 Monofilament bar fabrication

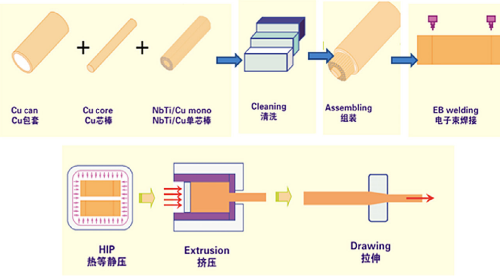

The monofilament bar is drawn into a hexagonal shape so that it can be restacked to create the final multifilament wire (see Fig. 9). The assembly process should be finished in a clean-room environment because any hard particulate incorporated into the billet could result in strand fracture at small size. After electron beam welding, hot isostatic pressing, and several times of drawing, the multifilament bar will be aged via heat treated and drawn alternately. Aging heat treatments are applied after sufficient cold work. For the Nb-47 wt% Ti alloy, the required prestrain is usually from 4% to 6%. Heat treatments are typically from 375 to 420°C for 20 to 80 h.The strain between heat treatments is usually from 0.8% to 1.5%, and at least three heat treatments are usually applied. α-Ti precipitates with the volume of ~20% of filaments are sufficient to obtain a critical current density of higher than 3000 A/mm2 at 5 T and 4.2 K.

Fig. 9 Multifilament bar fabrication

Applications

International thermonuclear experimental reactor (ITER)

ITER project is one of the largest international scientific research cooperation projects in the world. The aim is to build a nuclear fusion reactor to verify the scientific and technological feasibility of peaceful use of nuclear fusion energy. To achieve this goal, two hydrogen isotopes—deuterium (D) and tritium (T)—need to be heated to over 100 million degrees centigrade.

ITER magnet system is mainly composed of the following parts: 18 toroidal field (TF) coils, 1 center solenoid (CS), 6 poloidal field (PF) coils, 9 pairs correction field coil (CC), and compensating coil (Feeder). The magnet system with low-temperature superconducting wires is the core component of the ITER facility. The critical temperature (Tc) of the NbTi superconducting wire is 9.7 K, and its critical field (H) can reach 12 T, which can be used to manufacture superconducting magnets with a magnetic field of 9 T (4 K) or 11 T (1.8 K). NbTi superconducting wire has good processing performance and high critical current density, and its conductor still has 1.5 K temperature allowance under the rated conditions. Hence, it is selected as the conductor materials of poloidal field (PF) magnet coils for ITER. WST has delivered about 174 tons of NbTi superconducting wires for PF coils and CC/Feeder coils.

Magnetic resonance imaging (MRI)

Magnetic resonance imaging (MRI) is a medical imaging technique used in radiology to form pictures of the anatomy and the physiological processes of the body in both health and disease. MRI scanners use strong magnetic fields, electric field gradients, and radio waves to generate images of the organs in the body (see Fig. 10). Energy from an oscillating magnetic field is temporarily applied to the patient at the appropriate resonance frequency. The excited hydrogen atoms emit a radiofrequency signal, which is measured by a receiving coil.

Fig. 10 Magnetic resonance imaging system

MRI requires a magnetic field that is both strong and uniform. Most clinical magnets are superconducting magnets, which require a liquid helium environment. MRI consumes about 2500 t of NbTi superconducting wires (WIC wire) per year. As this type of NbTi superconductor has high copper/NbTi ratio, high RRR, and high critical current, it is not only highly reliable for MRI but also helpful to lower the cost of MRI.

Nuclear magnetic resonance (NMR)

NMR is a physical phenomenon in which nuclei in a magnetic field absorb and re-emit electromagnetic radiation. This energy is at a specific resonance frequency that depends on the strength of the magnetic field and the magnetic properties of the isotope of the atoms. NMR allows the observation of specific quantum mechanical magnetic properties of the atomic nucleus. Many scientific techniques exploit NMR phenomena to study molecular physics, crystals, and noncrystalline materials through nuclear magnetic resonance spectroscopy. NMR is also routinely used in advanced medical imaging techniques. Monolith NbTi wires with high n value, high diameter precision, low Copper/NbTi ratio of 1.3–4.0, and fine diameter of 0.4–1.5 mm are used in NMR magnets (Fig. 11).

Fig. 11 500 MHz NMR system

Magnetic field-applied czochralski crystal growth system (MCZ)

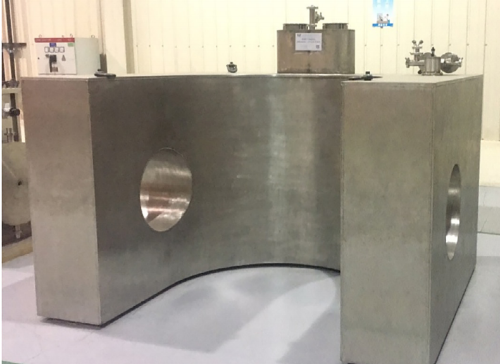

In the MCZ system, a magnetic field is applied to the molten semiconductor material, thereby controlling the molten semiconductor material heat convection. High-quality monocrystalline silicon ingot with large diameter can be manufactured by the MCZ system. Fig. 12 shows a conventional MCZ system. This MCZ system is comprised of a magnetic field generator and a growing furnace. Semiconductor material in the growing furnace is melted, so that the crystal can be pulled upward from the molten semiconductor material. The magnetic field generator generates a magnetic field, which is applied to the molten semiconductor material in the growing furnace. Growing furnace includes a furnace body, a crucible, a heater, a crucible support mechanism, and the lifter. The elevator is designed to melt from the crucible in the pulled semiconductor crystal material and the lifter mechanism rotating relative to each other, whereby the crystal and crucible rotating relative to each other. The magnetic field generator is mounted on the bracket, around the furnace body. The generator is comprised of a superconducting coil having a built-in cryostat. Monolith NbTi wires with high copper/NbTi ratio more than seven and with the shape of rectangle and round are used in MCZ magnets.

Fig. 12 MCZ magnet

High energy particle accelerator

A particle accelerator is a machine that uses electromagnetic fields to propel charged particles to nearly light speed and to constrain them in well-defined beams. Large accelerators are used for basic research in particle physics. The most powerful accelerator currently is the Large Hadron Collider (LHC) near Geneva, Switzerland, built by CERN. It is a collider accelerator, which can accelerate two beams of protons to an energy of 6.5TeV and cause them to collide head-on, creating center-of-mass energies of 13TeV. Other po werful accelerators are KEKB at KEK in Japan, RHIC at Brookhaven National Laboratory, and the Tevatron at Fermilab. Accelerators are also used as synchrotron light sources for the study of condensed matter physics. Smaller particle accelerators are used in a wide variety of applications, including particle therapy for oncological purposes, radioisotope production for medical diagnostics, ion implanters for manufacture of semiconductors, and accelerator mass spectrometers for measurements of rare isotopes such as radiocarbon. There are currently more than 30,000 accelerators in operation around the world . Rutherford cable of NbTi wires with the total critical current higher than 10,000 A (4T and 4.2 K) is used in particle accelerator magnets.

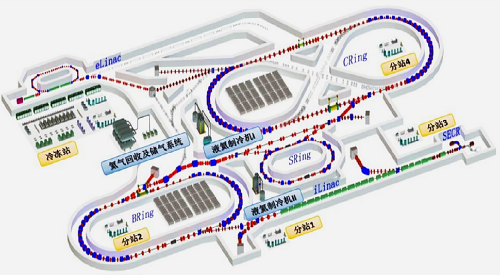

High-intensity heavy-ion accelerator facility (HIAF)

The high-intensity heavy-ion Accelerator Facility (HIAF) is a new engineering project proposed by the Institute of Modern Physics (IMP) of China. Superconducting magnets will be used as part of the accelerator magnets. To obtain high beam intensities, fast-pulsed magnets are required for synchrotrons. When operating in a fast-pulsed cycled mode, the superconducting cable will dissipate power (so called AC loss), which affects the stability of the magnet. The main contribution of the AC losses in superconducting wire are hysteresis loss and eddy current losses. Fine filaments design can reduce the hysteresis loss, and a resistive (Cu-0.5% Mn or Cu-5-10% Ni) interfilamentary matrix can reduce the interfilamentary eddy current losses. In addition, small twist pitch in superconducting wire is also required. WST has developed two types of superconducting wires with the matrix of CuMn and CuNi, respectively, for the HIAF project (Fig. 13).

Fig. 13 The overall layout of HIAF

Magnetic separation

Magnetic separation is a process in which a magnetically susceptible material is extracted from a mixture using a magnetic force. This separation technique can be used for selecting iron as it will be attracted to the magnet.It is also used in electromagnetic cranes that separate magnetic material from scraps. Another application, not widely known but very important, is to use a magnet to remove metal contaminants from product streams. Major breakthroughs have been achieved in superconducting technology and applied in industrial production. Monolith NbTi wire with Copper/NbTi ratio from 1.3 to 7 and with the shape of rectangle is used in magnetic separation magnets.

Magnetic levitation (Maglev)

Maglev is a system of train transportation that uses two sets of magnets, one set to repel and push the train up off the track as in levitation, and the other set to move the floating train ahead at great speed taking advantage of the lack of friction. In electrodynamic suspension (EDS), both the guideway and the train exert a magnetic field, and the train is levitated by the repulsive and attractive force between these magnetic fields

Superconducting liquid level meter for superconducting magnet

To ensure its stable operation, the superconducting magnet must be immersed in liquid helium, and thus the liquid level must be detected. One type of liquid level meter is NbTi wire with a matrix of CuNi alloy. Because the magnet quench may occur in the excitation process, the fast flow of helium within the magnet may damage the liquid level meter. To ensure the reliability, it is necessary to arrange two superconducting liquid level meters. In this way, when a fault occurs, one is switched to the other one.

Summary

High-performance ductile NbTi superconducting wires are manufactured as a commodity product for applications where large and uniform magnetic fields are required. XOT has successfully developed different types of NbTi superconducting wires, including Monolith NbTi superconducting wire, wire-in-channel (WIC) NbTi superconducting wire, and superconducting cables. These wires and cables have found wide applications in international thermonuclear experimental reactors (ITER), magnetic resonance imaging (MRI), nuclear magnetic resonance (NMR), magnetic-field applied czochralski crystal growth systems (MCZ), high energy particle accelerator, high-intensity heavy-ion accelerator facility (HIAF), superconducting liquid level meter for superconducting magnets, magnetic separation, and magnetic levitation (Maglev). Just for MRI applications, the global annual demand is approximately 90,000 to 100,000 km. This means that NbTi superconducting wires still have a huge market in the future.