Niobium-titanium (i.e. the NbTi alloy near the ratio of 1:1) is a well-known superconductor with a critical transition temperature (TC) of about 10 K at zero magnetic field. Due to its distinguished combined properties of superior high critical magnetic field and high critical supercurrent density, together with its accessible superconducting transition temperature, its affordability, and its easy workability, the NbTi alloy, among thousands of the known superconductors, has been one of the most important material for fabricating commercial superconducting magnets which are widely used in physics, chemistry, materials science and biology. However, the knowledge on the properties of this material under extreme conditions is still lack. Understanding the response of superconductors to extreme conditions such as pressure can uncover the unknown properties of the known materials,and consequently expand their applications.

NbTi superconducting wires applications

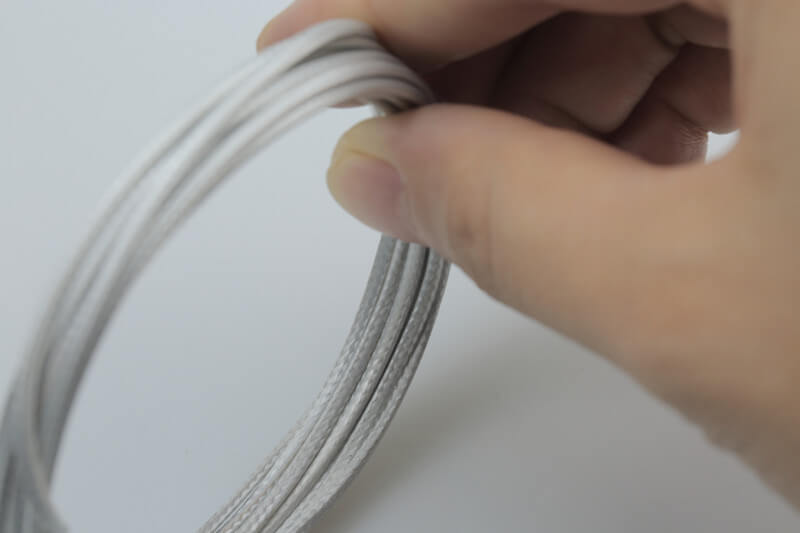

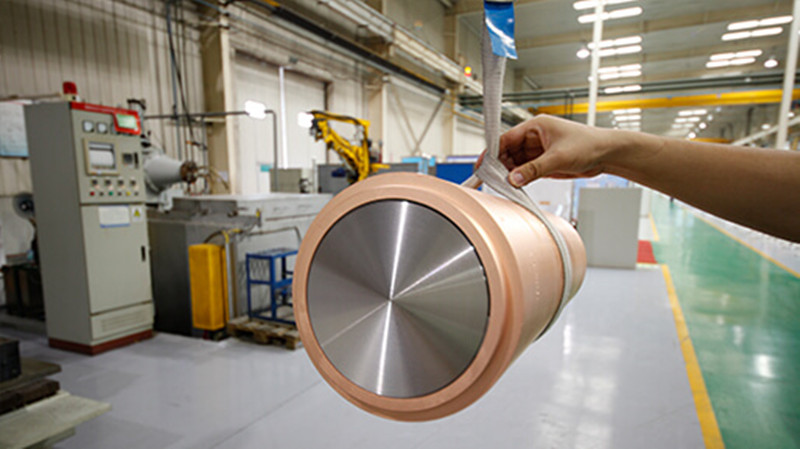

At present, high-performance ductile NbTi superconducting wires are manufactured as a commodity product for applications where large and uniform magnetic fields are required. XOT metals has successfully developed different types of NbTi superconducting wires, including Monolith NbTisuperconducting wire, wire-in-channel (WIC) NbTi superconducting wire, and NbTi superconducting cables. Economical performance costs, excellent ductility, and favorable processing properties as well as durability and reliability make NbTi the unrivalled workhorse of today’s superconductor industry.

Operated under standard conditions at temperatures of 4.2 Kelvin, they carry current densities of up to 3,000A/mm² and enable magnetic fields up to approx. 9.5T.

The principal NbTi wire market is clinical magnetic resonance imaging (MRI), nuclear magnetic resonance (NMR), magnetic-field applied czochralski crystal growth systems (MCZ), high energy particle accelerators, high-intensity heavy-ion accelerator facilities (HIAF), superconducting liquid level meter for superconducting magnets, and magnetic separation and magnetic levitation (Maglev).Please contact us for more information.