Introduction to Nickel-Titanium (Ni-Ti)

Today the main area of application for shape memory alloys, especially Nickel-Titanium (Ni-Ti) alloys , is medical technology. This was also the first market in which nickel-titanium alloys were able to establish themselves. The prime example for the use of shape memory alloys in medical technology is the stent, a vasodilating mesh used to support arteries and veins. Shape memory alloys are also frequently used in the dental industry, for example in brace wires. The purpose of these is to apply a constant tension over a large deformation path of the teeth. Shape memory alloys are also used for so-called root canal files, which are required for preparing the root canal. Due to the special properties of nickel-titanium, root canal files based on nickel-titanium alloys are able to file around the curve without causing the material to break.

Ni-Ti shape memory alloys

Ni-Ti shape memory alloys are those types of memory alloys that are made using nickel-titanium. , in roughly equal amounts. Apart from these two elements, others that can be used to make shape memory alloys are copper, zinc, gold, and iron but Ni-Ti is the most common memory alloy. There are many reasons for using these two elements for making smart alloys, the major ones of which are given below:

Ni-Ti shape memory alloys are preferable because they are stable, and practical and showcase superior thermo-mechanic performance as compared to other metals.

- The yield strength of Ni-Ti-based SMAs is less than that of steel but it is known that certain compositions can give a better yield than plastic and even aluminum. In fact, the yield stress of Ni-Ti can go to 500 MPa.

- Using Ni-Ti-based alloys can result in a high level of recoverable plastic strain induced.

Nitinol Dental Brace, Shape Memory NiTi Alloy Dental Brace

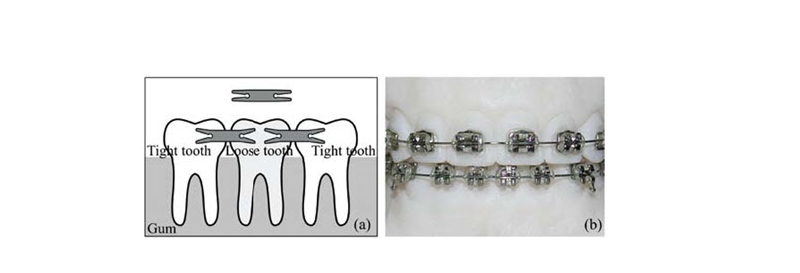

Nickel Titanium Alloy has a soft finish, making comfortable to wear frames. If they are bent accidentally, the wearer can return the frames to their original shape by immersing them in hot water. Nitinol is well known for its thermo-mechanical properties of superelasticity and shape memory effect. Shape memory refers to the ability of Nitinol to undergo deformation at one temperature and then recover its original, under formed shape upon heating above its transformation temperature. Super elasticity occurs at a narrow temperature range just above its transformation temperature; in this case, no heating is necessary to cause the under formed shape to recover, and the material exhibits enormous elasticity, some 10-30 times that of ordinary metal. Nitinol is a nickel-titanium alloy with the typical ratio 40-50% nickel, 50-60% titanium known as a shape memory alloy (SMA), a metal alloy that demonstrates pseudo-elasticity and the shape memory effect. The shape memory effect is when a material returns to its pre-deformed shape by heating. These unusual properties are being applied to a wide assortment of applications in a number of different fields including the medical device and aerospace industries.Traditional stainless steel wires have a tendency to lose tension over time. When the wire becomes slack, an orthodontist must readjust the wire. By using nitinol for the archwire, an orthodontist can mold the wire to the current shape of your teeth. Once the wire is placed in your mouth, it will begin to heat up. As it heats up, the wire will try to reform into its original straight shape.

As the memory wires try to straighten out, they will exert gradual pressure on your teeth. Pressure over time is how teeth are moved in orthodontistry.

Ni-Ti Rotary Files in Endodontics

Nickel-Titanium (Ni-Ti) alloys have gained significant attention in the field of dentistry, particularly in endodontics, due to their unique properties.

Ni-Ti rotary files have revolutionized the field of endodontics by providing a more efficient and effective way to shape and clean root canals. These files are designed to:

- Reduce instrumentation time: Ni-Ti rotary files can prepare root canals more quickly than traditional stainless steel files.

- Improve canal shaping: The flexibility of Ni-Ti alloys allows for more accurate shaping of the canal, reducing the risk of transportation or perforation.

- Enhance safety: The superelasticity of Ni-Ti alloys reduces the risk of file breakage, making the instrumentation process safer for patients.

and develop new applications? Then XOT metals is at your side with comprehensive product and alloy development know-how. Contact us today to talk now!