All niobium-based alloys are solid solution strengthened alloys. The most commonly used alloying elements are zirconium, titanium, hafnium, tantalum and tungsten.

The alloy Nb-1Zr can be used in nuclear applications because it has a low thermal neutron absorption cross section, good corrosion resistance and good resistance to radiation damage. It is widely used in the liquid metal disposal system at a temperature of 980-1205.

Nb-1Zr can withstand the corrosion of sodium vapor under high temperature and high pressure, so it is used for the production of sodium vapor lamps on highways.

The improved Nb-1Zr contains 1% C and is used in liquid alkali metal containers in space nuclear power systems.

Alloys C-129 Y (Nb-10W-10Hf-0.1Y), FS-85 (Nb-28Ta-11W-0.8Zr) and Cb-752 (Nb-10W-2.5Zr), have better than C-103 High temperature tensile strength and creep strength, but also maintain good processability, coatability and thermal stability. They are used for wing leading edges, anterior vertebral bodies on hypersonic aircraft, rockets, nozzles, gas turbines and reentry Guidance mechanism for atmospheric vehicles.

The basic niobium-titanium alloy.

Ti6AL7Nb in ASTMF1295

Because of the addition of metal niobium, it has better compatibility with human tissues and muscles and has a longer service life.

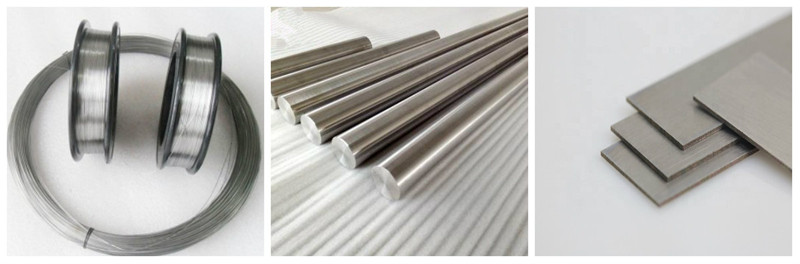

Mainly use shape in, wire, bar,sheets.

The rods/wires Dia 2.5mm, Dia3.2mm, Dia6.6mm

- Ti6AL7Nb wires for high elasticity kirschner wireCharacteristic : High corrosion resistance ,high tensile strength ,good el;asticity The stock size Dia1.0- Dia4.0mm

- Ti6AL7Nb bars and rods for dental implantsCharacteristic : Good elasticity,high strength ad good metallographic structure The stock size :Dia5-20mm

- Ti6AL7Nb medical bars and surgical implantsCharacteristic : good biocompatibility ,max screw fracture torsion and angle ≧200 degree

- Ti6AL7Nb sheets and platesThe stock size:thick 1.0-6.0mm * 300-400mm*1000-1500mm Tolerance : 0.08m-0.15mm

- Characteristic :

- High precision : thickness tolerance 0.04-0.15mm, straightness within 1mm/m,surface smoothness Ra ≤ 0.16um

- High property : Tensile strength can reach above 1000Mpa

- Microstructrure A1-A4

- NDT ( nondestructive testing ): within AA grade

NbTi47 in ASTMB884

Superconducting Product is one of the most widely used materials in engineering applications such as Magnetic Resonance Imaging (MRI), Nuclear Magnetic Resonance (NMR), Physics Research, and Fusion Energy and Science project Customized and the big effort is making to develop the customized superconductor for meeting the client’s demand.

Mainly use shape in, wire, bar,sheets

NOTICE: All superconducting materials must be used at a low temperature of 4.2 to have an effect..

If the user cannot provide cryogenic equipment, we will provide supporting YBCO molds according to customer requirements to ensure the best effect of niobium titanium products.

- NbTi47 RodsSpecification :Custom Made

Size : Dia6.35-190mm* 1000

Inventory size:Dia180mm/Dia114mm/Dia129mm/Dia190mm *500-800 - NbTi Wires/CoilsSpecification :Custom Made

Diameter: 0.5-2.0mm*L - NbTi47 Tubes/PipesSpecification :Custom Made

Size: OD1-160*T0.15-16mm*6000mm - NbTi47 Plates/SheetsSpecification :Custom Made/ASTMB393

Size: 1-20mm *8-800mm *400-500

Nbti 55 ( Grade 36 in ASTMB348 or Custom made specificaiton)

Since it is harder and stronger than other Nbti grades, which used in components of cell conductor or blade turner and superconducting RF resonators or the equipements of Nuclear plant

Mainly use shape in discs,ring and flanges

The attachment is the chemical composition and its advantages compared to other materials

Other grades

The niobium alloys Nb-46.5 Ti, NbTi47, and Nb55ti alloys used to develop superconducting magnets can be used as fasteners for aerospace agencies

Please contact us to know more about niobium and niobium alloy products.