Descriptions of Niobium

Niobium is a kind of refractory rare metal with steel gray luster. Its melting point is 2467℃ and density is 8.6g/cm3. Niobium has good low-temperature plasticity and can be cold-pressed into rods, sheets, wires and other products. Niobium can withstand high temperature and high strength, and still has sufficient strength, plasticity and thermal conductivity above 1000°C. Superconductivity is best at extremely low temperatures. For example, its resistance is close to zero at minus 260°C. It is currently the most important superconducting material.

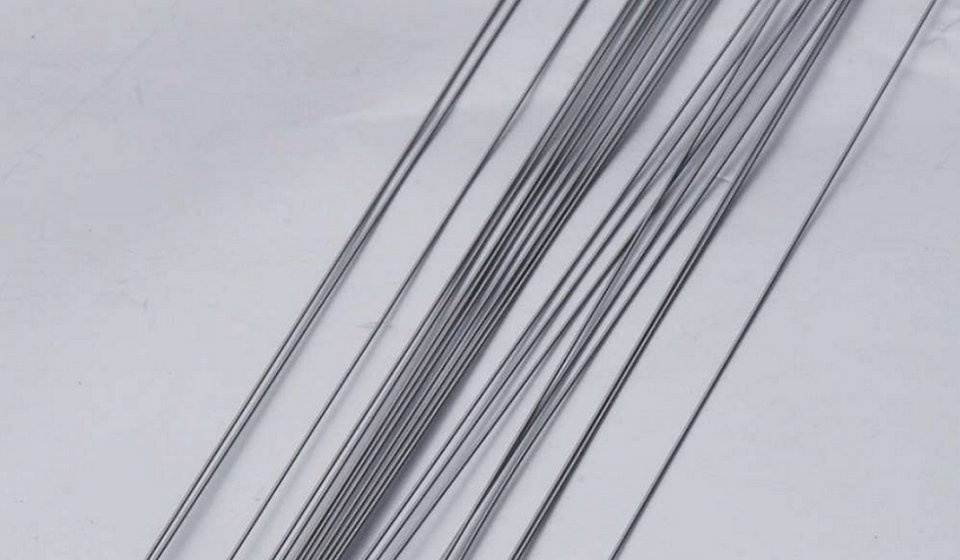

Niobium capillary tube, also called niobium fine pipe, is always used in the petrochemical industry, aerospace, and electronics industry. XOT metals provides customized Niobium Capillary Tube or Mirco Pipe with high-quality and at a competitive price.

Niobium Capillary Tube / Pipe Specifications

Outer diameter: Φ0.2-Φ8mm

Wall thickness: T0.015-0.5mm

Tolerance: Outer diameter: Φ±0.003mm

Wall thickness: T±0.005mm

Length: L±0.05mm

Specification size: customer’s special size and requirements can be negotiated

Niobium Capillary Tube Application

- High-pressure sodium lamp production.

- Heat exchange pipe in the heat exchanger.

- Thermometer protection pipe in the petrochemical industry.

- Aerospace, electronics industry.

XOT metals is a supplier of niobium and niobium alloy tubes, our products include pure niobium tubes, niobium-zirconium alloy tubes, niobium-tungsten alloy tubes, and niobium-titanium alloy tubes. The size can be customized. Usually used in the medical and aerospace industries.

Manufacturing Process of Niobium

Niobium tubes are manufactured by electron beam melting technology, including seamless niobium tube and welding niobium tube. First, melt the not forging niobium bar into niobium ingot by vacuum electron beam melting technology. There are two ways of smelting – single smelting and multiple smelting. Usually we smelt two times, or it can be more than two times depending on the product specific requirements. Second, forging and axial breakdown niobium ingot and then make it into niobium tube bloom by extrusion process manufacturing, then take it for annealing treatment and cleaning. After several times of rolling and annealing, we get the high quality niobium tube. The performance of this kind of technology is uniform, mainly used to produce small specification pipe and capillary materials, applicable to the production of various specifications of products.

Properties of Niobium

Niobium is a shiny, white, ductile metal. In air an oxide layer forms whose color depends on its thickness. Shades of blue, green and yellow are typical.

Niobium resists corrosion due to the oxide film. The metal starts to oxidize rapidly in air at 200oC. • Niobium’s chemical properties are very similar to those of tantalum.

Niobium is one of the five major refractory metals (metals with very high resistance to heat and wear). The other refractory metals are tungsten, molybdenum, tantalum and rhenium.

Niobium and high-temperature niobium-tungsten alloy materials are widely used in aerospace engines, weapon thrusters, rocket and missile liquid two-component engines, nuclear reactors, submersibles, gas turbines, automobile engines, diesel engines, high-temperature furnace heating belts, high-temperature molds, Manufacturing of high temperature fixtures and high temperature crucibles.

Applications of Niobium

• Used for the heat exchange tube.

• The protect tube of thermometer in petrochemical industry

The electronics industry.

• Niobium is used for the production of high-temperature-resistant alloys and special stainless steels.

• Small amounts of niobium impart greater strength to other metals, especially those that are exposed to low temperatures.

• Niobium carbide is used in cutting tools.

• It is used in stainless steel alloys for nuclear reactors, jets, missiles, cutting tools, pipelines, super magnets and welding rods.

• Niobium-tin and niobium-titanium alloys are used as wires for superconducting magnets capable of producing exceedingly strong magnetic fields.

• Niobium is also used its pure form to make superconducting accelerating structures for particle accelerators.

• Niobium alloys are used in surgical implants because they do not react with human tissue.

Types of Niobium Products

| Niobium Hollow Pipe | Niobium Heater for High Temperature |

|---|---|

| Niobium Seamless Pipe | Niobium Heat Exchanger Tube |

| Niobium Bush Hex Pipe | Potassium-doped Niobium Wire |

| Niobium Round Pipe | Niobium Welded Pipe |

| Niobium Alloy Round Pipe | Niobium Rotating target |

| Niobium Aero engine tube | Niobium Custom Pipe |

| Niobium Alloy Custom Pipe | Niobium Thick Wall Pipe |

| Niobium Elliptical and Oval Tube | Niobium Thin Wall Pipe |

| Niobium Pipe Fittings | Niobium Forging |

| Niobium Strips | Niobium Fasteners |

| Niobium Flex pipe | Niobium Plates, Sheets and Bars |

| Niobium Alloy Polished Pipe | UNS Niobium lined pipe |

| Niobium Exhaust Pipe | Niobium Micro Tube |

| Niobium Bar/Billet | Niobium Wire/Welding Wire |

| Niobium Boiler Tube | Niobium Coil Tubing |

| Niobium Capillary Tube | Niobium U Shaped Tube |

| Niobium Rods | Precision Niobium Tubing |

| Niobium Ingots | Niobium Foil |

| Niobium Metals | Niobium Crucibles |