Description

Niobium is a shiny silver-white metal; covered with a bluish oxide film. Niobium was discovered in 1801 by the English scientist Charles Hatchet in a mineral sent back in 1734 to the British Museum from Massachusetts by John Winthrop (grandson of John Winthrop Jr.). The mineral was named columbite, and the chemical element was named “columbium” in honor of the country from which the sample was obtained – Colombia (at that time a synonym for the United States).At XOT metals, niobium cube is available in 99.95% purity (excluding Tantalum).

In 1802 A.G. Ekeberg discovered tantalum, which coincided in almost all chemical properties with niobium, and therefore for a long time it was believed that this is one and the same element. It was only in 1844 that the German chemist Heinrich Rose established that it was a different element from tantalum and renamed it “niobium” in honor of Tantalus’s daughter Niobe, thereby emphasizing the similarity between the elements. However, in some countries (USA, England) the original name of the element – Colombium – remained for a long time.

For the first time, pure niobium was obtained at the end of the 19th century by the French chemist Henri Moissant electrothermally, reducing niobium oxide with carbon in an electric furnace.

Niobium is a chemical element with the symbol Nb, atomic number 41 and atomic weight of 92.90638. It is a lustrous transition metal with a silver color. The most useful property of the metal is the ability to strengthen alloys at low temperatures. Niobium alloys are commonly used in jet engines and rockets.

Great for chemistry and physics experiments or as a scientific desk toy.

General Properties

| Symbol | Nb |

|---|---|

| Atomic Number | 41 |

| Atomic Weight | 92.9064 |

| Density | 8.57 g/cm3 |

| Melting Point | 2468 ℃ |

| Boiling Point | 4742 ℃ |

| Thermal Conductivity | 0.537 W/cm/K @ 298.2 K |

| Electrical Resistivity | 12.5 microhm-cm @ 0 oC |

| Electronegativity | 1.6 Paulings |

| Specific Heat | 0.064 Cal/g/K @ 25 oC |

| Heat of Fusion | 6.5 Cal/gm mole |

Details

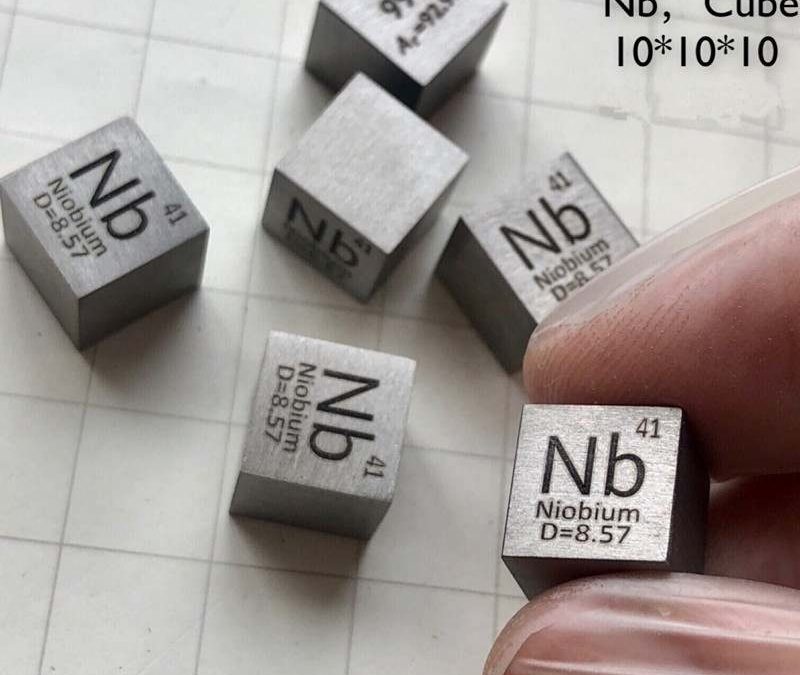

A Standard Density Cube of Niobium which weighs 8.58 grams with a tolerance of ± 0.1 gram

exactly as the theoretical density of the Niobium itself = 8.58g/cm^3

Material: Niobium metal;

Purity: W≥99.95%

Range of application: element collection, education, gift and so on.

Features

- 10mm density cube made of 99.95% pure Niobium metal

- Each Niobium cube made from high purity metal and featuring attractive, ground surfaces and laser etched labels

- Precision machined for super flat facets and 0.1mm tolerance to come very close to theoretical density

- Every cube perfectly finished with sharp edges and corners and no burrs.

Niobium Metal Production Technology

Due to the malleability of niobium material, it can be cold forged, rolled, punched, pulled, spun, extruded, bended and other process.

Heat process should be operated in a vacuum or protected environment.

Heat treatment process should be taken in vacuum and below 1100-1200°C. Time of heat preservation is determined by the quantity and thickness of materials. niobium foil can not be stacked when recrystallization annealing.

Surface treatment: shutter grinding wheels are usually used to remove surface peeling, scratches and other defects, and then non-woven abrasive cloth is used to mechanically polish scratches on the surface to make the surface uniform.

Cutting and grinding performance: to reduce the phenomenon of adhesion, extrusion and surface roughness in cutting, coolant should be used.

The common welding methods are tungsten electrode argon arc welding, laser welding, electron beam welding, diffusion welding and brazing.

Niobium parts have many different shapes such as niobium tube, niobium bend, niobium flange.

Application

- Make for Jewelry;

- Sodium Vapor Lamps;

- Capacitors, metled cast ingots and alloying agents.

- For steel, ceramics, electronics;

- nuclear energy industries, superconductor technology.

For more information on niobium, please contact us. XOT metals provide expert advice and high quality custom product.