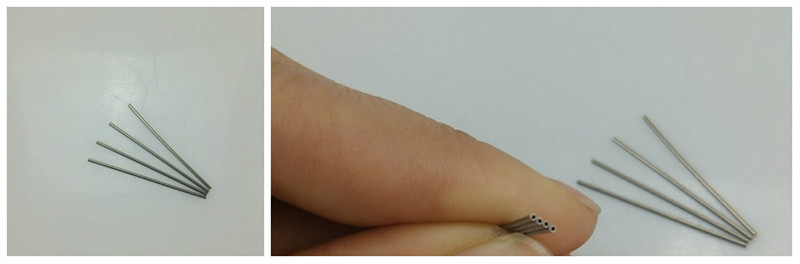

Specification: OD(0.5-5)mm*WT(0.05-0.3)mm*L

Application:mainly in medical device industry

Nitinol capillary tube used in implantable medical devices including Heart valves, peripheral vascular stents, cardio stents, neurovascular stents etc.

Medical devices use requires high quality surface on Nitinol tubing. The technology and tube making processes developed by Vascotube have been perfected over many years of practice. Using our experience, combined with new technologies and custom made machinery, we have been able to develop a drawing process that avoids the need for slurry cleaning, chemical cleaning or mechanical removal operations on the inner surface of the drawn tube. Our process allows us to attain a roughness value of Ra 0,1 µm.

Active Austenite Finish Temperature

The austenite finish temperature of the finished tube (Active Af) with outer diameter in the range of 0.3 to 3.0 mm (0.012 to 0.12 in.) shall be measured on representative full round tube sample(s) using the bend and free recovery method described in Test Method ASTM F 2082-15.

Mechanical Properties

| Condition | UTS Mpa | Elogation % | Upper Plateau Stress Mpa | Parmanent set after 6% strain % | Acyive AF ℃ |

|---|---|---|---|---|---|

| Superelastic | ≥1000 | ≥10 | ≥380 | ≤0.5% | ≤20℃ |

Superelastic properties are measured per Test Method F 2516 at room temperature (22+/-2C)

Applicable Standard: ASTM F2633

Medical Application

- Guide Tube

- Needle

- Dental Products

- Nitinol Tube Components

Surface Finish

- Outer surface: oxide or center-less-ground.

- Inner surface: Etched or oxide

- Other finishes can be discussed with Peiertech

Our Advantages

- More than 16 years experience in the processing of nitnol products.

- The complete production line makes us control the quality from beginning to finishing

- We have excellent research team that 5 engineers can always supply the exact solution for you.

- The testing items we do covering all properties you like.

- Customized sizes are available

Welcome to enquiry!