Introduction

Since the late 1980’s, the superelastic behavior of shape memory material and in particular, Ni-Ti alloys has been extensively exploited by the medical device industry. Superelastic NiTi has become a material of strategic importance as it allows to overcome a wide range of technical and design issues relating to the miniaturization of medical devices and the increasing trend for less invasive and therefore less traumatic procedures.

The key characteristics of a superelastic material offers both designers and users an interesting compromise between polymers and conventional metals. The “Strength of a metal and the flexibility of plastics” or “Super-spring” qualifiers have often been attributed to superelastic nitinol.

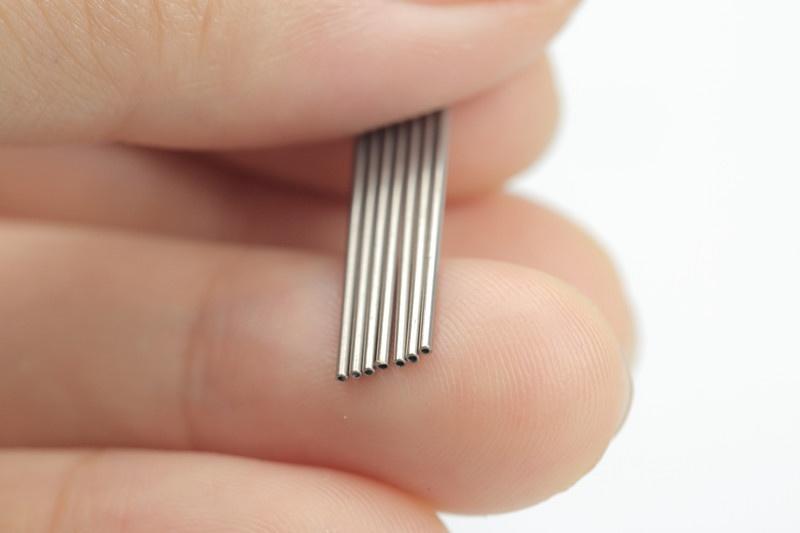

Due to its unique properties and biocompatibility, nitinol tubing has seen its strongest proponents among the designers of less invasive medical devices as its elevated price tag has limited its entry in mainstream industrial or commercial applications. From catheters to superelastic needles, from stents to other implantable structures, nitinol tuning has become one of the material of choice for many medical device companies just like stainless steel and titanium. Kink or crush-resistance, flexibility, large recoverable deformations, good fatigue life and outstanding superelastic behavior at or around the body temperature have allowed the application of nitinol tubing in order to reduce and minimize critical medical device sizes and perform functions not possible with other materials. Today, it offers the best compromise between engineered plastics and traditional metals. Nitinol tubing is typically manufactured in the range of 0.10 mm to about 10mm outside diameter in discrete length up to 3 meters long and offered in a straight cold-worked and heat treated condition.

The key characteristics of a superelastic material offers both designers and users an interesting compromise between polymers and conventional metals. The “Strength of a metal and the flexibility of plastics” or “Super-spring” qualifiers have often been attributed to superelastic nitinol.

The most important and relevant properties of superelastic nitinol can be listed as follows:

- Advantages relating to the superelastic behavior:

- Large recoverable deformation

- Low permanent set or residual deformation

- High plateau stresses and ultimate tensile strength

- Body temperature within superelastic temperature range (50 at% Ni – Ti)

- High potential energy storage capability

- Corrosion resistance similar to stainless steel and titanium alloys

- Biocompatibility

Cold-worked and heat treated to superelastic condition nitinol wires have been used for years to produce dental arches or medical guidewires. The introduction of superelastic tubing has opened new frontiers and an all-new set of design and product capabilities.

One can obviously appreciate the need for a ‘working lumen’ in a variety of applications and fine gage stainless steel tubing or hypodermic tubing has been used extensively in these cases. Nitinol tubing has allowed alleviating many of stainless steel’s intrinsic elastic limitations.

Alloy and size availability

The vast majority of all nitinol tubing currently manufactured is drawn from the very typical 50 at% Ni alloy composition. This alloy has well documented superelastic characteristics at room and around body temperature making it an ideal candidate for a variety of medical device applications. When the thermal shape memory effect is required, a warmer binary composition (50.6 at% Ni) have also been drawn successfully into small gage hypotubes.

Attempts (on a smaller scale) at drawing ternary alloy compositions were also successful but the market demand has not yet justified larger amounts of efforts in this area therefore these alloys tends to be drawn only on a custom basis and at a higher cost.

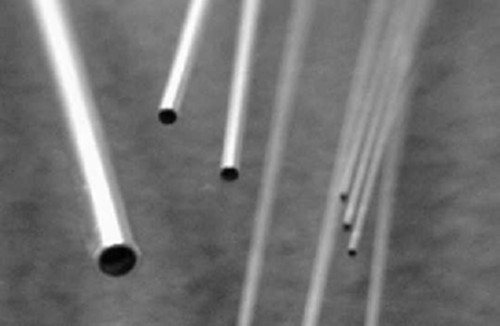

Nitinol tubing is typically manufactured from 0.15mm to about 6mm outside diameter but larger sizes are also available on a more limited and customized basis (up to 15mm).

Nitinol tubing is always supplied in discrete length (up to 3.5 meters,and in the cold-worked and heat-treated condition.

Finishes include as-drawn and centerless ground outside surface conditions. Optional inside diameter slurry and/or honing treatment are available as well as chemical passivation for enhanced corrosion resistance.

Methods of manufacture

Nitinol tubing is drawn in a seamless condition usually starting from gundrilled barstock often referred to as hollows.

Typical tube drawing techniques are employed by most manufacturers:

- Floating plug

- Hard mandrel

- Sinking (drawn without internal mandrel or plug)

Except from the later, both floating plug and hard mandrel technique require either the plug or the mandrel to be replaced in between draw passes to achieve the subsequent pass and reduction in diameter.

Manufacturing nitinol tubing remains a challenging and costly exercise but is progressing at a fast pace, smaller gages and thin wall tubing are now available in part dictated by a strong demand from the medical device community.

If you want to know more about nitinol tubing, please Contact us .