Weaving textiles from nickel-titanium (NiTi) wires offers a way to give garments a ‘shape memory’ where they can return to their original shape after being deformed by applying heat. new ways to make and process wires to take advantage of the numerous, exciting applications of their NiTi wire technology, including in the manufacture of protective clothing for firefighters and astronauts.Nitinol springs have a two-way shape-memory effect in both hot and cold environments, enabling sensing, actuating, and controlling of the microclimate temperature of the clothing system without any external power supply.

Imagine a dress that, no matter how much you crumpled it up or wrinkled it, could pop back to its original shape, just with a little heat. Imagine clothing that could move and morph designs, just by changing the temperature of the environment. All of this can now be achieved in the era of ‘smart’ or ‘technical’ textiles, where new technologies are being combined with traditional textile manufacturing to create high performance materials with a whole variety of exciting applications.

These applications are not just limited to clothing either – technical textiles can now be found in bandages that have enhanced antibacterial properties to reduce the probability of post-operative infections.

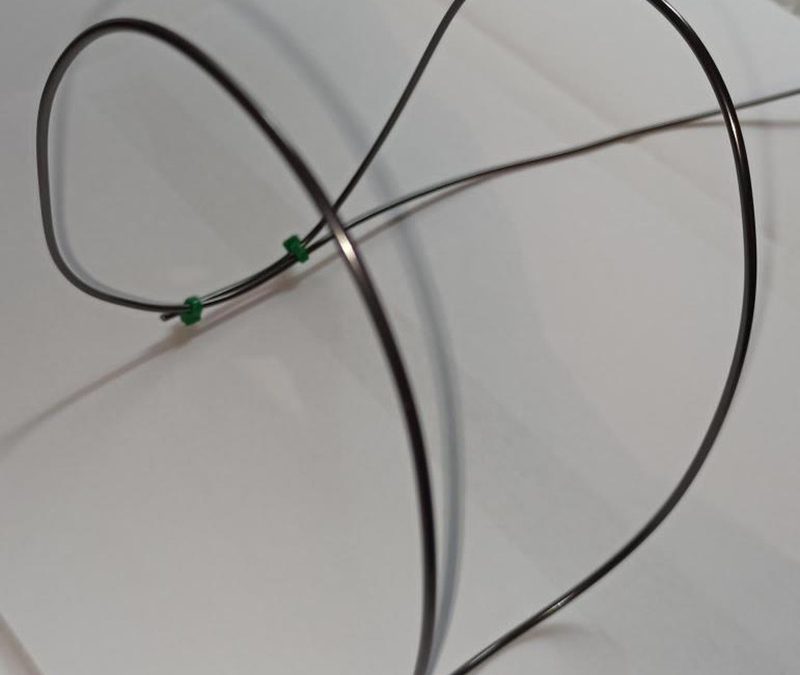

Among these, one of the most exciting developments is the use of shape memory alloys in technical textiles. These are materials that can be set into a shape and, no matter how they are distorted, they will return to their original shape on heating.

Nitinol Springs for Protective Clothing of power workers

Nitinol metal will be inserted into working vest (to be positioned on the shoulder). Whenever there is an electrical field, we have a custom made circuit, our circuit will heat up the wire at i.e. 45-50-60C and wire will stress the shoulder, so will warn the operator about the electrical filed with feeling / stressing / stretching on him.

So, it need the wire to have that memorized shape at 45C or 50C or 60C.

Embedding NiTi wires into textiles enables the engineering of a complex 3D structure thanks to the shape setting. Such NiTi structures can repeatedly undergo large strains thanks to both NiTi atoms shuffling back and forth, and wavy geometry of NiTi wires allowing for large deflections. These NiTi structures may be extremely compliant and soft at one temperature while becoming stiff and hard upon being heated by just a few degrees.

Nitinol springs for sanitary project.

Designation : Nitinol Springs wire diam 2.3mm

Technical specifications : Ni 54,4% / Ti 45,4%,

As=40°C

In addition, we also provide nickel-titanium springs for other industrial applications

Two way-Shape Memory

Nitinol springs that restore high-temperature phase shape when heated, and restore cooling temperature phase shape when cooled

One way-Shape Memory

Nitinol springs deform at lower temperature, restore the shape before deformation when heated. It only shows shape memory phenomenon when heating

Customization according to customer needs is our main way of supply. Not only will it be sales materials, but our professional technical staff can provide suggestions according to the customer’s application.

Given the complex nature of Nitinol and of course its spring form. Feel free to contact us anytime to talk about your product needs, and our experienced engineers will be happy to recommend or design the spring that will fit your needs.