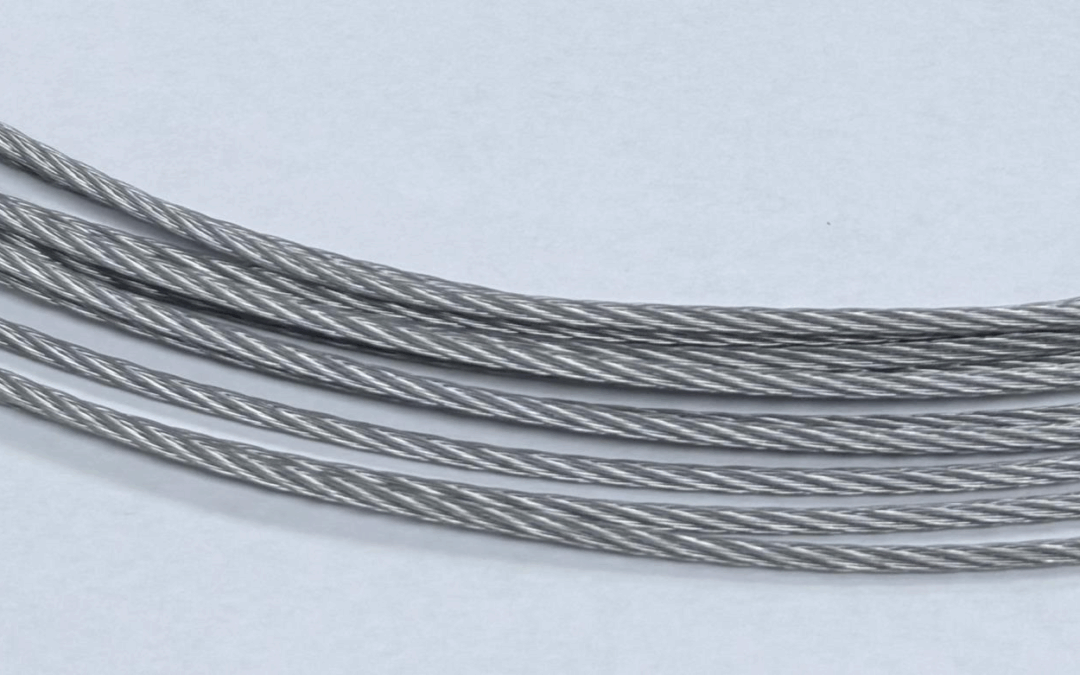

Shape memory nitinol wire rope is a remarkable material that combines the adaptability of wire rope structures with the distinctive properties of nitinol, a nickel-titanium alloy. Due to its remarkable capacity to remember and return to its original shape after deformation, this innovative product has revolutionized numerous industries. Shape memory nitinol wire rope’s fascinating applications, unrivaled characteristics, and cutting-edge technologies will all be revealed during this comprehensive investigation. This extraordinary material continues to push the boundaries of what is possible in material science and engineering, from aerospace engineering to medical devices.

The Unique Properties Of Shape Memory Nitinol Wire Rope

Understanding The Shape Memory Effect

The foundation of the remarkable capabilities of nitinol wire rope is the shape memory effect. When heated above a predetermined transition temperature, this phenomenon enables the material to “remember” its original shape. This behavior is attributed to a solid-state phase change that can be reversed between two crystal structures at the molecular level: austenite and martensite The nitinol takes on a martensite structure that is more malleable and easy to deform as it cools. It returns to the austenite phase upon heating, regaining its original form with surprising force and precision.

Superelasticity: A Game-Changing Characteristic

Supplementing the Shape memory nitinol wire rope is nitinol’s superelastic property. Because of this property, the wire rope can withstand significant deformation without suffering any permanent damage and return to its original shape when the stress is removed. At temperatures above the material’s austenite finish temperature, where the applied stress causes a phase change from austenite to martensite, superelasticity occurs. Nitinol wire rope is invaluable for applications requiring flexibility and durability because of its unique behavior, which enables it to withstand extreme bending and twisting without fatigue or breaking.

Biocompatibility And Corrosion Resistance

Shape memory nitinol wire rope is a popular choice for medical applications due to its exceptional biocompatibility. It outperforms even stainless steel in its resistance to corrosion in bodily fluids and tissues. Because of this and the fact that it is not magnetic, it can be safely used in medical devices and implants. In addition, the material’s capacity to maintain its properties over a broad temperature range ensures consistent performance in the human body, further establishing its status as a revolutionary biomaterial.

Applications Of Shape Memory Nitinol Wire Rope

Aerospace And Aviation Advancements

Shape memory nitinol wire rope has revolutionized aircraft design and performance in numerous aerospace applications. It is ideal for making adaptive wing structures because it is light and can change shape in response to changes in temperature. During flight, these morphing wings can change shape, maximizing aerodynamic efficiency and fuel efficiency for various flight conditions. Additionally, vibration damping systems use nitinol wire ropes to reduce noise and enhance passenger comfort in aircraft cabins. The material’s resistance to fatigue and corrosion also makes it useful for making aerospace components that last a long time.

Medical Marvels: Transforming Healthcare

Shape memory nitinol wire rope has been welcomed with open arms by the medical community, which has utilized its distinctive properties to develop ground-breaking treatments and devices. Nitinol wire ropes are used to make guidewires and catheters for minimally invasive surgery. These devices can navigate through intricate vascular systems with unprecedented ease and precision. These devices can be inserted into the body in a compact form due to the material’s shape memory effect, and once inside the body, they expand to their functional shape. Nitinol-based orthodontic archwires facilitate tooth movement with consistent, gentle force, reducing patient discomfort and treatment time. Most impressively, self-expanding stents made of nitinol wire ropes can be compressed for insertion and then expanded to their full size once in place to restore blood flow to blocked arteries.

Robotics And Automation: Enabling New Possibilities

In the quickly developing field of advanced mechanics, shape memory nitinol wire rope is opening ways to new plans and capacities. It is an excellent alternative to conventional actuators in robotic systems because it can expand when cooled and contract when heated. The development of lightweight, compact robots with fluid, lifelike movements is made possible by this property. Nitinol wire ropes are used to create flexible, adaptable structures in soft robotics that can safely interact with humans and navigate complex environments. The material’s durability as well as its high strength-to-weight ratio make it useful for making robotic exoskeletons, which can improve human strength and mobility in industrial and medical settings.