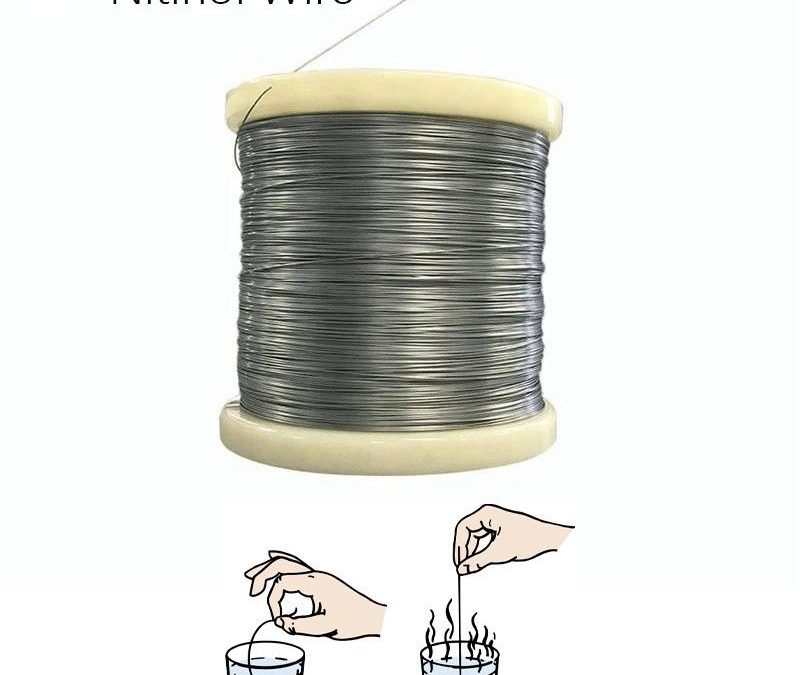

Nitinol Wire Description

Nitinol wire are the fabricating product of nickel-titanium alloy. Nitinol is well known for its thermo-mechanical properties of superelasticity and shape memory effect. Shape memory refers to the ability of Nitinol to undergo deformation at one temperature and then recover its original, under formed shape upon heating above its transformation temperature.

Super elasticity occurs at a narrow temperature range just above its transformation temperature; in this case, no heating is necessary to cause the under formed shape to recover, and the material exhibits enormous elasticity, some 10-30 times that of ordinary metal.

Chemistry: Typical

| Element | Min | Max |

|---|---|---|

| Nickel | 55% | 56% |

| Titanium | 44% | 45% |

Physical Properties

Density, 0.2633 lbs/in³, 6.45 g/cm³

Electrical Resistivity: Ω-cm

Austenite: 82 x 10

Martensite: 76 x 10

Thermal Conductivity, W/cm°C

Austenite : 0.18

Martensite: 0.086

Mean Coefficient of Thermal Expansion, in/in/°F (μm/m•K) 80- 200°F (27- 93°C)

Austenite: 6.1 x 10 (11)

Martensite: 3.6 x 10 (6.6)

Modulus of Elasticity, KSI (MPa)

Austenite: 10.08-12.04 x 10³, (75-83 x 10³)

Martensite: 4.06-5.80 x 10³, (28-40 x 10³)

Melting Point: 2930°F (1310°C)

Mechanical Properties Of Nitinol Wire At Room Temperature

NITI Properties: Annealed Typical

Ultimate Tensile Strength: 130 KSI (895 MPA)

Yield Strength (0.2 Offset):

Austenite: 28-100 KSI (195-690 MPa)

Martensite: 10-20 KSI (70-140 MPa)

Elongation: 25-50%

Specifications for our shape memory wire and superelastic alloy wire

| Product Name | Nitinol wire |

|---|---|

| Specification | ASTM F2063-12 |

| Af Temp. | -10°C to 120°C |

| Size | 0.004”-0.2” Diameter x L Regular wire, 0.1mm min diameter |

| Surface | Black, Pickled, Polished (Dia.>0.04”) |

| Available Shape | Straight, Coils, On Spools |

| Applications | Dental braces, Stent, Fishing wire, Springs, etc. |

| Other wire type | Square wire, rectangular wire, Multi-strand nitinol wire and other customized shape |

Alloy Type

Two way-Shape Memory

Nitinol wire that restore high-temperature phase shape when heated, and restore cooling temperature phase shape when cooled

One way-Shape Memory

Nitinol wire deform at lower temperature, restore the shape before deformation when heated. It only shows shape memory phenomenon when heating

How does Nitinol remember its shape?

When a shape memory alloy is in its martensitic form, it is easily deformed to a new shape. However, when the alloy is heated through its transformation temperatures, it reverts to austenite and recovers its previous shape with great force. This process is known as shape memory.

How strong is Nitinol?

The Nitinol Memory toy is made of nitinol wire with a low transition temperature (the temperature of hot water). The force generated when the wire is reverting is surprisingly strong. One square inch of Nitinol material generates a shape returning force of + 30,000 PSI.

Can Nitinol be bent?

Bending is the predominant deformation mode in Nitinol medical devices and components. Many of these applications also impose cyclic bending loading conditions. These results can be used as the basis of a constant life diagram for fatigue-resistant design of medical devices.

What is af temperature?

Austenite finish temperature (Af) – the temperature at which martensite (or R-phase) to austenite transformation is completed on heating of the alloy. Martensite deformation temperature (Md) – the highest temperature at which martensite will form from the austenite phase in response to an applied stress.

Transition Temperatures

Nitinol changes its crystalization pattern at more than 1 temperature point. The stoichiometric ratio of Ni to Ti, impurities, and post-processing determine the mechanical characteristics of your nitinol.

All transition temperatures are specified in Celsius ºC. The temp indicated is an approximation of where the alloy begins to undergo the crystalline transformation. It occurs over a fairly wide temperature range. So, a 40C rated wire will perform faster and stronger at 80C.

At room temperature, an 80C wire will be substantially more malleable and soft to your fingers, the 40C will be more difficult to bend, and the 15C will feel like spring steel. The 15C will react to a heat source up to 80C, while 80C NiTi is more suitable for exposure up to 150C. The 15C will be malleable at and below freezing temperatures.

How do Nitinol work?

The properties of Nitinol rely on its dynamic crystalline structure. The molecular structure is sensitive to external stress and temperature. The alloy has three defined temperature phases:

- Austenite Phase – temperature is above activation temperature. The transition temperature varies depending upon the exact composition of the Nitinol alloy. Nitinol comes in many activation temperatures from 30°C (86°F) to 130°C (266°F).

- Martensitic Phase – low temperature phase. The crystal structure is needle-like and collected in small domains. Within the small domains the needle-like crystals are aligned. The alloy may be bent or formed easily. Bending transforms the crystalline structure of the alloy producing an internal stress.

- Annealing Phase – high temperature phase. The alloy will reorient its (cubic) crystalline structure to “remember” its present shape. The annealing phase for the Nitinol wire is 500°C

Nitinol Wire Applications

Nitinol Wire is used for many different medical and industrial applications. The table below gives some typical engineering applications for each of our standard Nitinol medical grades:

- Nitinol Wire is used in guidewires, stents, stylets, forming mandrels, stone retrieval baskets, orthodontic files, etc.

- Nitinol Wire is often used in applications that require a high loading and unloading plateau stress at room temperature. Chromium-doped for decreased transformation temperature and increased tensile strength.

- Nitinol Wire is used in applications requiring increased stiffness. Cobalt-doped for decreased transformation temperature and increased tensile strength.

- Nitinol Wire provides the best cycling performances at body temperature (37°C).

- A common application for Nitinol alloy is high-temperature actuators.

- A common application for Nitinol alloy is high-temperature actuators.

- Nitinol Wire/Rod is typically used in applications that require a phase transformation at body temperature (37°C).

- Nitinol Wire/Rod can be used in a very cold temperature environment.

Xot manufactures nitinol wire (nickel titanium alloy wire) from various grades of nickel-titanium alloy (Nitinol) commonly used in medical applications as well for other various applications. Medical grade Nitinol material comprises nickel and titanium in nearly equal atomic weight percentages; per ASTM F2063, a nickel content of 54.5-57 wt% is specified for using in surgical implants. Nitinol (nickel titanium alloy) with different compositions and phase transformation temperature can be used for other applications.For more information,please contact us.Our Nitinol application sales engineers will be glad to help.