RRR Grade Niobium Introduction

With the growth of radio frequency niobium superconducting cavity design, RRR Grade Niobium is widely used in national and international world. The requests for niobium are also increased. Absolute pure metal only exists theoretically. Actually the metals we are applying more or less have impurities. Superconducting niobium usually contains O, C, N, H and Ta, Fe, W and etc. If the impurities are over limited range, the properties of superconducting niobium itself will be affected. Then its value will be influenced as high purity niobium superconducting material. Therefore, niobium RRR data is an important parameter to reflect purity and thermal conductance.

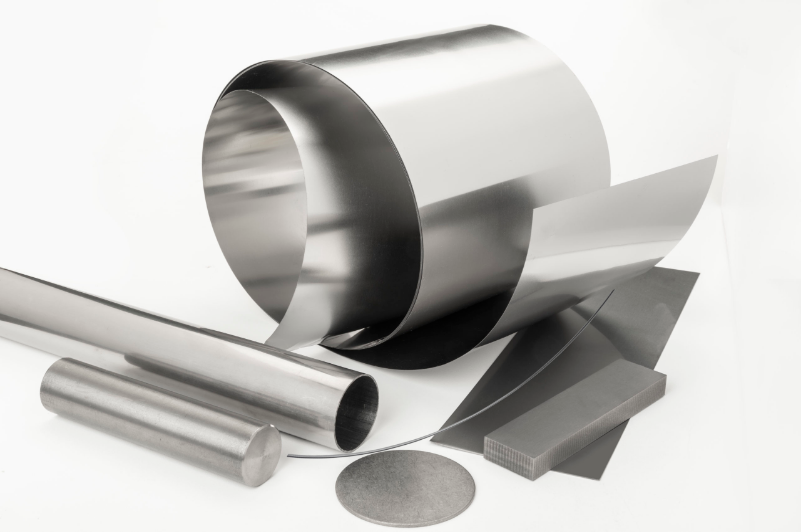

Niobium superconducting Residual Resistivity Ratio (RRR) is defined as the ratio of niobium superconducting resistivity and low temperature superconducting niobium resistivity under room temperature. With the increase of material’s purity and decrease of interior stress, RRR value is reduced. RRR value can be used to measure purity of the metal. Firmetal can produce Niobium products based on the RRR value customer required. RRR niobium is usually manufactured in shape of sheet, rod and tube. Regular dimension of sheet thickness is 2 to 5mm, while width is max 1000mm.

It is well-known that, among of all pure metals, niobium, with its high critical temperature and critical magnetic field, is the favorite material for the fabrication of superconducting RF cavities. Niobium is chemically inert (at room temperature the surface is covered by a protecting oxide layer), it can be machined, deep drawn, welded and it is available as bulk and sheet material in any size. For good performance of superconducting RF cavities a high thermal conductivity in the cavity wall is required to guide the dissipated radio frequency (RF) power to the liquid helium coolant. For bulk niobium cavities this demands niobium of high purity.

The residual resistivity ratio (RRR=300 for a high gradient cavity) is a common indicator of the level of purity. The main interstitially dissolved impurities, oxygen, nitrogen, hydrogen and carbon (O, N, H, C), act as scattering centers for unpaired electrons and reduce the RRR. Oxygen is dominant due to its high affinity to Nb. The influence of hydrogen on the RRR is not so significant, but the content of hydrogen should be kept small (less then 3-5 µg/g) to prevent hydride precipitation and degradation of the Q-value of the high RRR cavities under certain cool-down conditions.

Chemical requirements for RRR superconducting grade niobium (wt%, max.)

| UNS | C | N | O | H | Zr | Ta | Fe | Si | W | Ni | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R04220 | 0.003 | 0.003 | 0.004 | 0.0005 | 0.01 | 0.1 | 0.005 | 0.005 | 0.007 | 0.003 | 0.005 | 0.005 |

* Per ASTM B393-09

Mechanical properties for RRR superconducting grade niobium

| Grade | Condition | Tensile strength (MPa, min.) | Yield strength (MPa, min.) | Elongation in 1 inch (%, min.) |

|---|---|---|---|---|

| R04220 | Annealed | 95 | 50 | 30 |

* Per ASTM B393-09

* Annealed condition – 90 % Minimum Recrystallized

Available forms

Ingot

Rod

Plate and sheet

Specifications

ASTM B393-09

Typical application

Superconducting RF cavities