Tantalum and Tantalum Alloys

Tantalum is the third most refractory metal, with a melting point of 2980℃, only after tungsten and rhenium. Besides, tantalum also has other excellent properties like low vapor pressure, good cold workability, high chemical stability, strong resistance to liquid metal corrosion, and a large dielectric constant of the surface oxide film. Therefore, it has already been widely used in the industry and our everyday lifeTantalum (Ta) is a refractory metal that is ductile, easily fabricated and highly resistant to corrosion by acids, a good conductor of heat, electricity and has a high melting point 3020°C.

Production Method

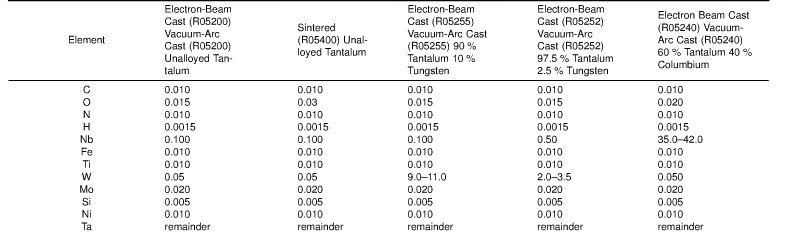

The preparation of tantalum and tantalum alloys is usually carried out in an electron beam furnace. In order to obtain a uniform ingot in the electron beam furnace, the vacuum arc melting is carried out. All tantalum and tantalum alloys will be cast in an electron beam furnace, as to whether vacuum arc melting (VAR) is used at the same time, and the number of melting times is determined according to the use of the specific product.

The Main grades

At present tantalum is mainly divided into unalloyed Tantalum (purity 99.95-99.99% ) and Tantalum alloys.

- Unalloyed Tantalum: R05200 R05400

- Tantalum alloy is divided into: tantalum-niobium alloy. Tantalum tungsten alloy and tantalum titanium alloy.

- Tantalum tungsten alloy:R05255(Ta10W), R05252(Ta2.5W)

- Tantalum-niobium alloy: R05240

- Tantalum titanium alloy: Custom made

Among the two alloys of Ta-w and Ta-Nb , they are mostly used to manufacture parts for aviation and space nuclear power systems.

Ti-Ta alloys have been investigated in the range of 30–95% Ta.5 Several compositions have been found to be of interest for medical devices. medical wire, orthopedic implant and stent.

Main Tantalum Alloys Mill products

The main shape of the product: Tantalum Plates, Tantalum Tubes, Tantalum Bars, Tantalum Wires,Tantalum Fasteners and Tantalum Crucible/boat

Please click here to check more details

Specific application and proportion of Tantalum alloys

The world’s annual consumption of tantalum is about 900t, of which about 60% is used in the electronics industry, about 22% is used in cutting tools, about 6% is used in super alloys, and about 3% is used in chemicals. The chemical industry is mainly valves and heat exchange Devices and plug-in heaters, such as Ta-7.5W alloy wire for valve springs in chlorination furnaces. In addition, tantalum has good affinity with human body fluids, so about 1% of the consumption is used in the medical field , The remaining about 2% is used for military purposes such as kinetic energy bombs and crucibles for smelting and sintering rare earth metals and plutonium metals.

Military: Rocket aircraft surgery, stealth fighter coating.

An alloy of tantalum has been shown to conduct electricity with zero resistance or superconductivity, from ambient pressure up to pressures like those that exist near the center of the Earth.

If more basic information you need or specific inquiry, please feel free to contact us.