Nitinol has a unique combination of shape memory, superelasticity, fatigue resistance and biocompatabilityThough many Nitinolapplications are invisible to the general public, some are quite familiar. Eyeglass frames made from Nitinol can be bent severely out of shape, but then return perfectly to normal. Also, some years ago, when cell phones had pull-out antennas, many of the antennas were made from Nitinol, allowing them to flex without breaking or permanently bending.

Another superelastic application, where you or your children may have experienced Nitinol, is in arch wires used for orthodontistry. The orthodontist takes a Nitinol wire and bends it, attaching it to the teeth. Because the wire is superelastic, it tries to return to its straight condition, and continually exerts a force on the teeth. This allows less frequent visits to the orthodontist to have braces tightened.

A number of lesser-known applications use Nitinol’s shape memory capability. A well-known computer manufacturer used a Nitinol device to eject PCMCIA cards. Also, Nitinolis used in couplings that join the ends of hydraulic tubing in aircraft. In a less serious application, Nitinol enables spoons from the magic shop to bend when placed in hot water.

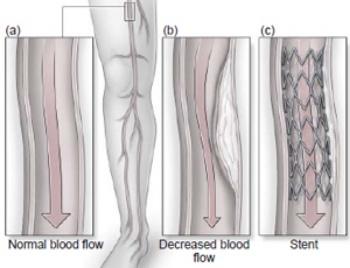

The superelastic quality of Nitinol, along with its biocompatability, makes it ideal for making many types of medical devices that are implanted in the body. An application familiar to many of us is the stent, a device that supports blood vessels and keeps them open. It’s superelasticity allows a medical device, such as a stent or a heart valve, to be compressed into a shape that fi ts inside a catheter. The catheter is positioned at the correct location in the body, the device is released, and it returns to its original shape.

This same superelasticity makes Nitinol the only material suitable for stents used in the carotid artery in the neck, or blood vessels in the legs. In these vulnerable locations, a blow to the area of a stent will cause it to deflect, but a Nitinolstent will return to its intended shape. Stents made of other materials would be subject to crushing or permanent bending by such an impact.

Surgical instruments and components made from Nitinol fill many needs, especially in minimally invasive or arthroscopic surgery. These may take advantage of the superelasticity and fatigue resistance of Nitinol. A tool that has a bend in it can be straightened and introduced through a cannula, a rigid tube. When it emerges from the cannula, the tool returns to its original shape. The surgeon performs the procedure, and then the tool is retracted back into the cannula where it straightens out again for easy removal.

Nitinol is available in various forms including wires, tubes, sheets and springs.

For more information on nitinol, please do not hesitate to get in touch with our friendly team today