Titanium is the ultimate solution to the problems that traditionally plague seawater tubing and piping leaks caused by corrosion/erosion and clogging caused by biofouling. Titanium is a proven solution to make corrosion resistant fasteners on vessels from ferries and fishing boats, to Naval ships and deep-sea submersibles, for heat exchangers, piping systems and dozens of other applications.

Thanks to the feature of corrosion resistance& lightness, titanium corrosion resistant fasteners has been widely used in marine and shipbuilding, yacht manufacturing, and marine engineering exploration projects, all they desire is titanium corrosion resistant fasteners can help ship come in with lower costs and better performance.

XOT Metals, as one of the leading suppliers of corrosion resistant fasteners and components for Marine Industry, provides screws and machined parts made of special non-ferrous materials such as niobium fasteners and components, molybdenum crucible & hex bolts, tantalum hex nuts & bolts and nickel components and fasteners

The marine pipelines with titanium fasteners, fittings and flange joints, without external damage, service life can exceed 30 years.

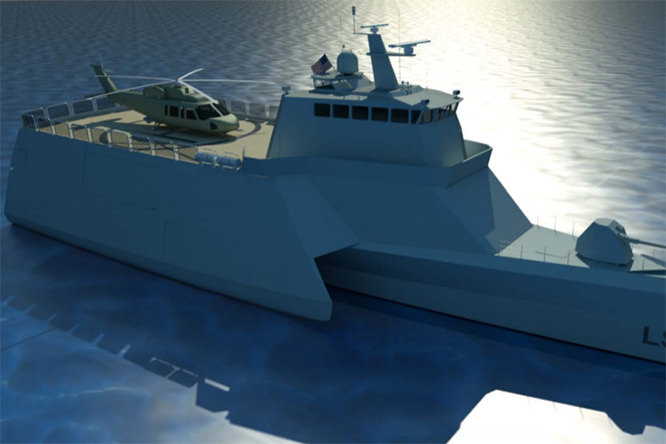

Corrosion Resistant Fasteners for Marine items

Corrosion Resistant Fasteners for Shipbuilding

We can provide more

Apart from the products listed below, other available metal products include Tantalum, Nickel Niobium, Zirconium etc., which are mainly in the form of Plate, Bar and Tube, XOT Metals can also provide.

| Products | Processing Standard | Grade | Size |

| Titanium Fastener (Bolts, nuts, washer, thread rod, etc) | DIN7, DIN84, DIN85, DIN912, DIN913, DIN963, DIN7991, DIN931, DIN933,ISO7380 and American Standard. DIN84, DIN912, DIN963, DIN7991, DIN933,ISO7380 | GR5,GR9,GR19,TB3 | M1.0-M24 |

If any customize issue, please Contact Us for details,